PLASTICS & COMPOSITES

Solutions for your pain

points in plastics processing

Dry ice blasting helps plastic manufacturers

reduce scrap and downtime, improve product

quality and prolong the life of their equipment.

CASE STUDIES

Revolutionise processes

to drive real results.

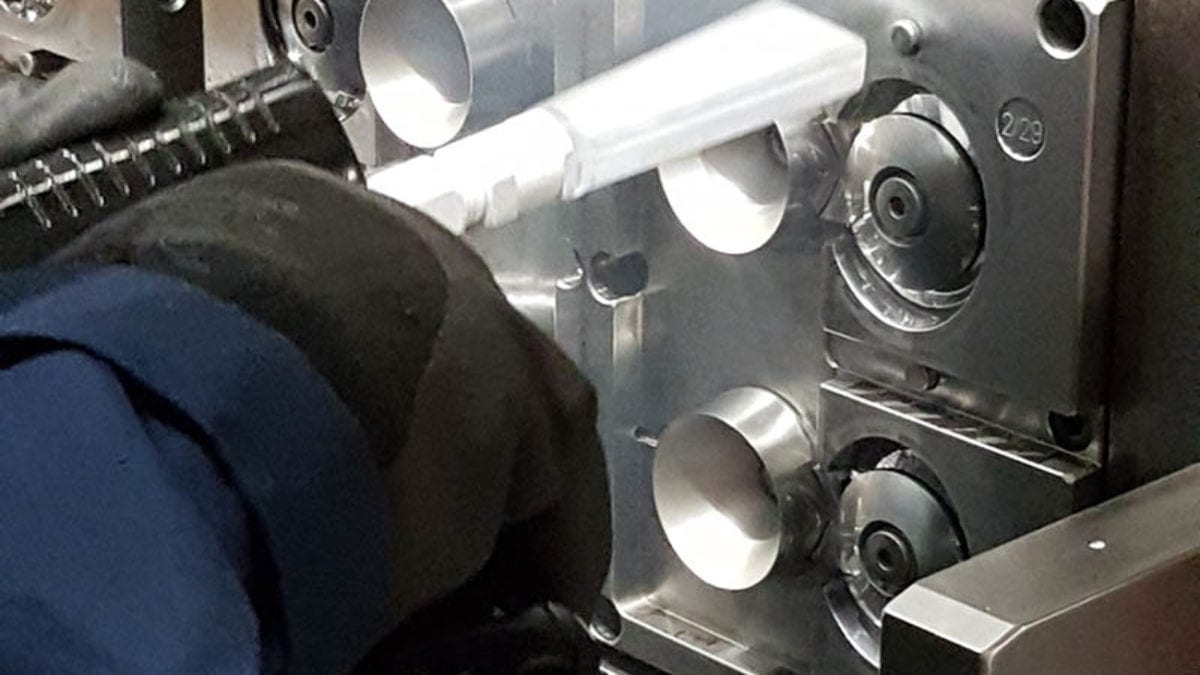

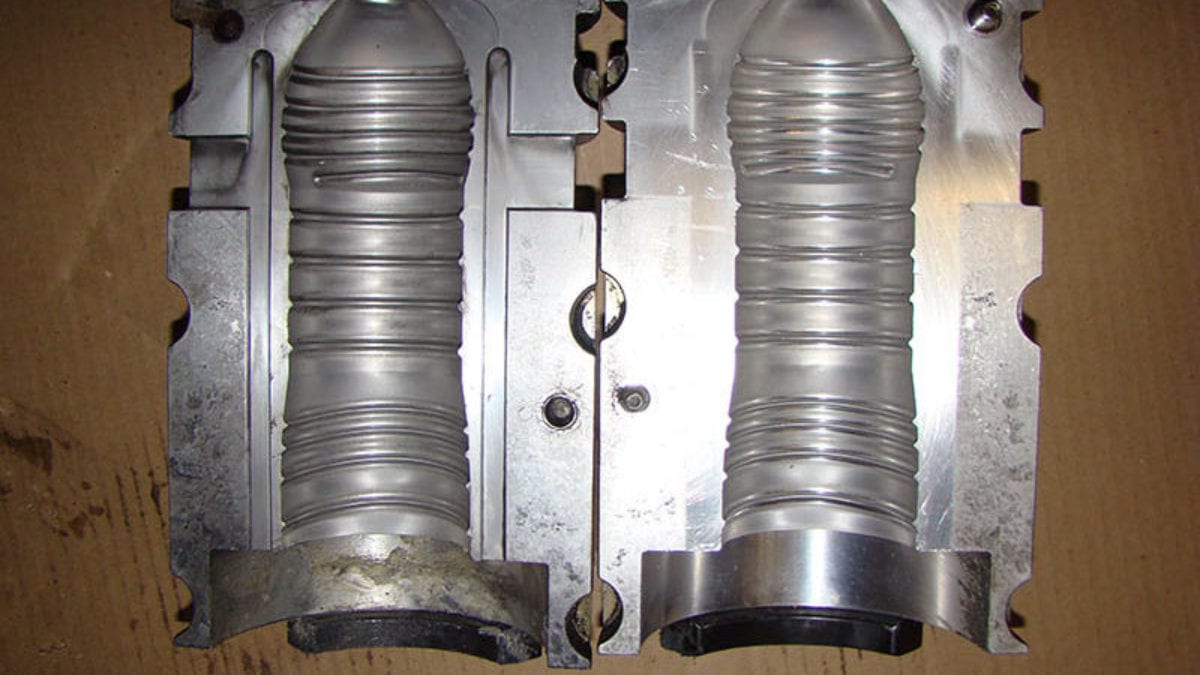

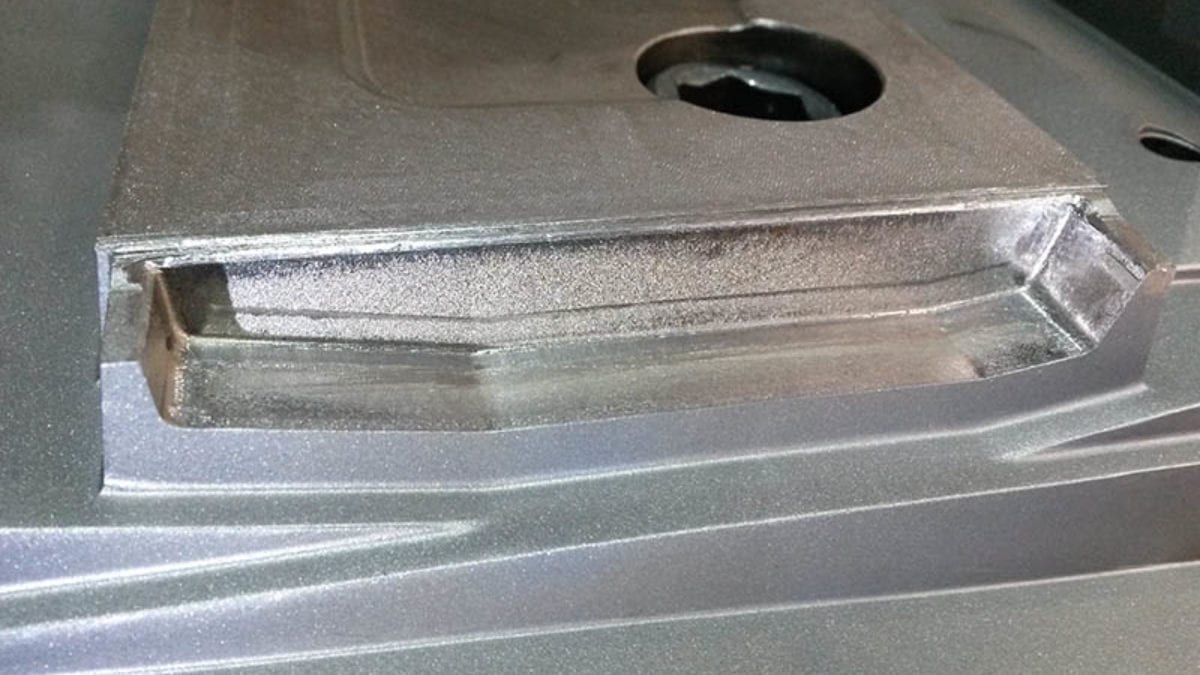

Mold Cleaning

Improve productivity by reducing downtime

BENEFITS

Dry ice blasting is a non-abrasive method that safely cleans moulds online, at operating temperatures.

- Improve product quality

- Clean in-place

Little to no disassembly required - Non-abrasive

No damage to moulds - Reduce scrap

Cleaner moulds lead to higher quality - Meet stringent industry demands

6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance) - Reduce production downtime

Clean quicker and without cooldown or disassembly - Decrease cleaning time and labor costs

- Eliminate painstaking manual cleaning

SPECIFIC USE CASES:

- Injection moulds

- Blow moulds

- Compression moulds

- Urethane moulds

- Textured moulds

- Slush moulds

- Technical moulds

- Extrusion dies

- Rotational moulds

- LSR and LIM moulds

- Thermoform moulds

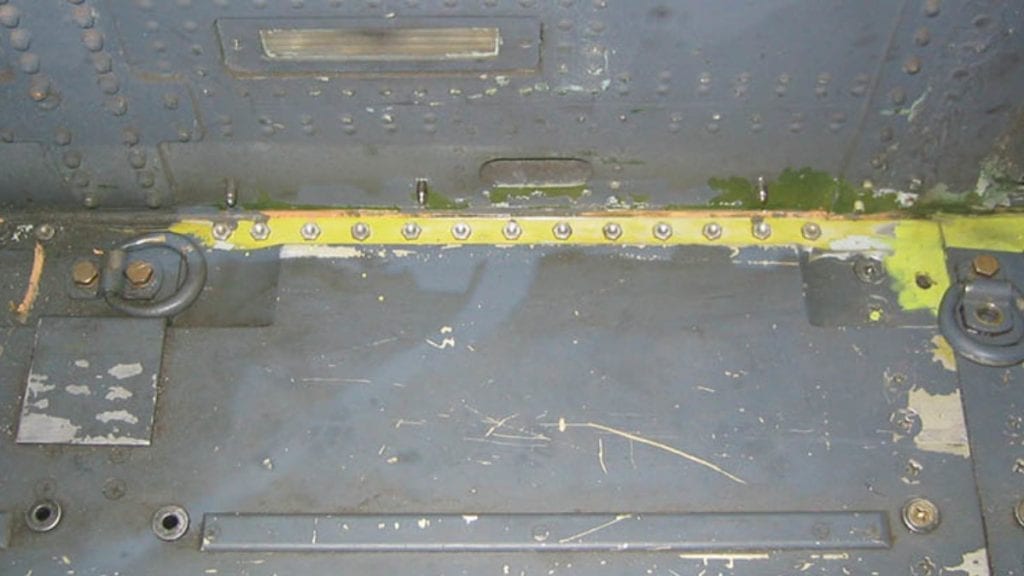

Surface Preparation

Prepare surfaces with a dry process that allows

for immediate coatings/paint application

BENEFITS

Dry ice cleaning is a dry process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate paint or coating after cleaning

- No secondary waste

Reduce disposal costs - Non-abrasive

Will not damage parts - Improve product quality

- Environmentally responsible

SPECIFIC USE CASES:

- Interior parts

- Exterior parts

- Cleaning surfaces before RTVs

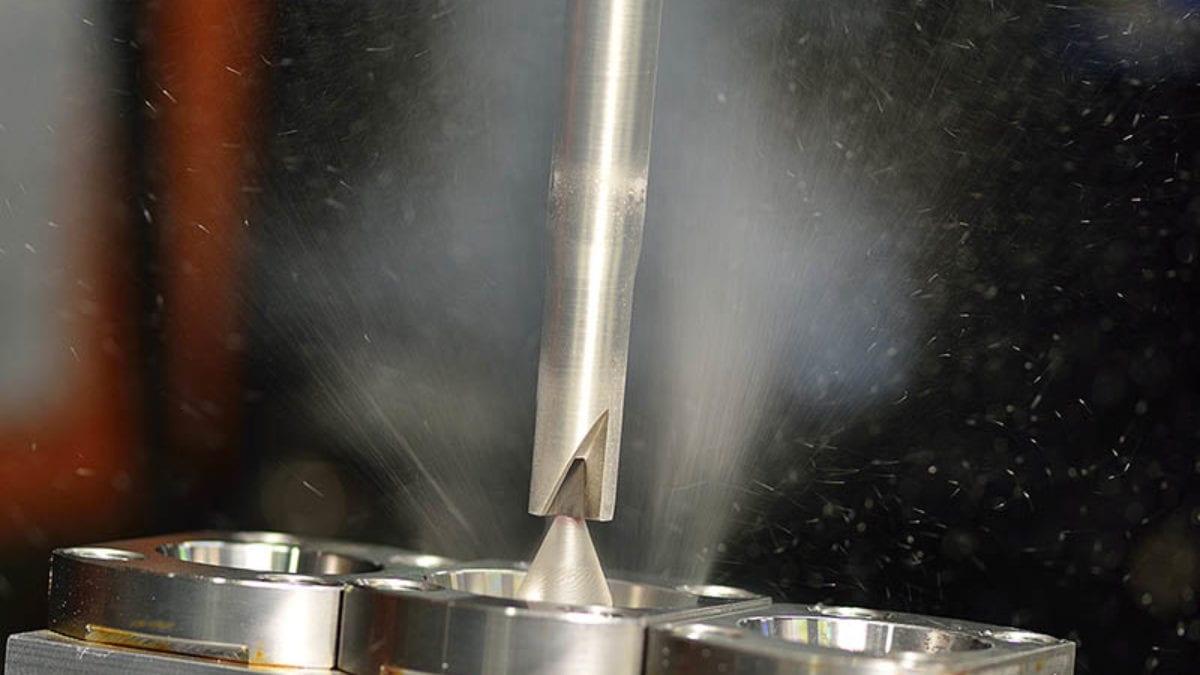

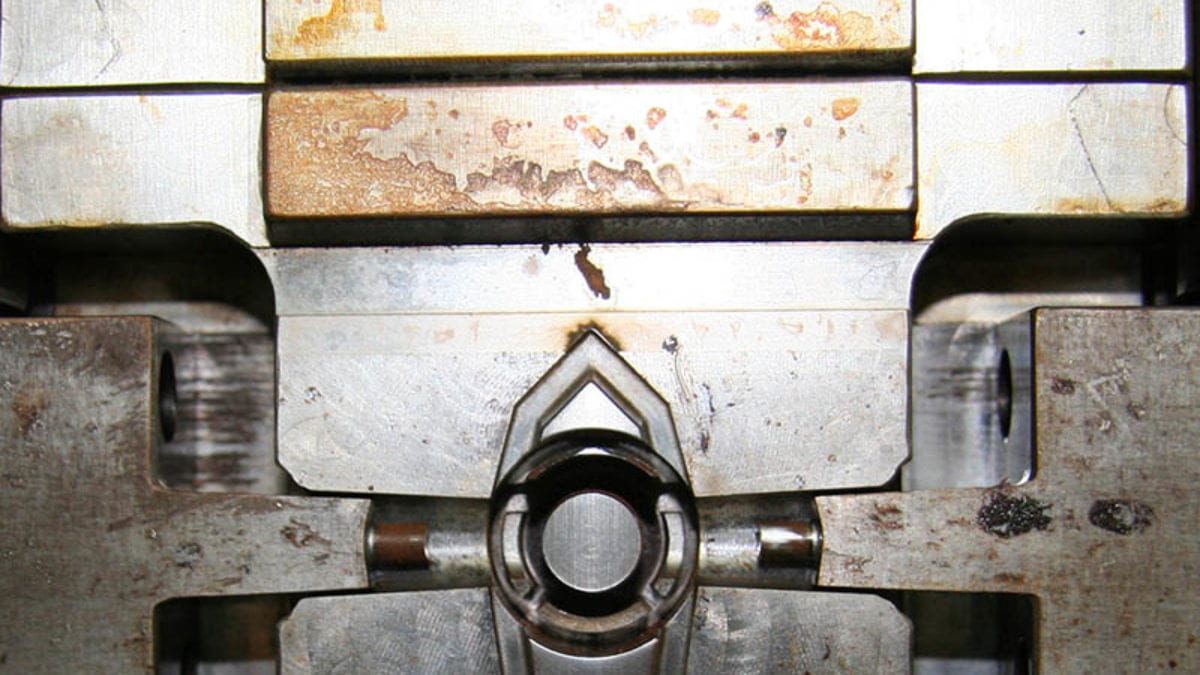

Parts Finishing Cleaning

Quickly and safely deburr and deflash parts

BENEFITS

Dry ice cleaning is a faster and more uniform flash and burr removal process that does not cause damage to the part.

- Faster and more uniform clean

- Elimination of cross contamination

- Non-abrasive

Lower scrap rates - Reduce cleaning costs and overall downtime

- Higher quality parts

- Eliminate manual cleaning

SPECIFIC USE CASES:

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- ABS

- UHMWPE

- Nitinol

BENEFITS OF DRY ICE BLASTING

Maintain high quality standards

while improving productivity

The unique benefits of dry ice make it the perfect cleaning media for plastics processors.

→ Improve part quality

→ Reduce scrap

→ Reduce production downtime

→ Decrease cleaning time and labour costs

→ Clean in-place

No disassembly required

→ Non-abrasive

No damage to product or equipment

→ Environmentally responsible

No secondary waste

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning