AEROSPACE & AVIATION

Safely clean a variety of parts

and equipment while maintaining

high quality standards

Dry ice blasting helps Aerospace manufacturers meet stringent

industry demands. The process safely removes many types of

contaminants from a variety of surfaces for maintenance purposes,

safety inspections and as a surface preparation prior to painting.

CASE STUDIES

Revolutionise processes

to drive real results.

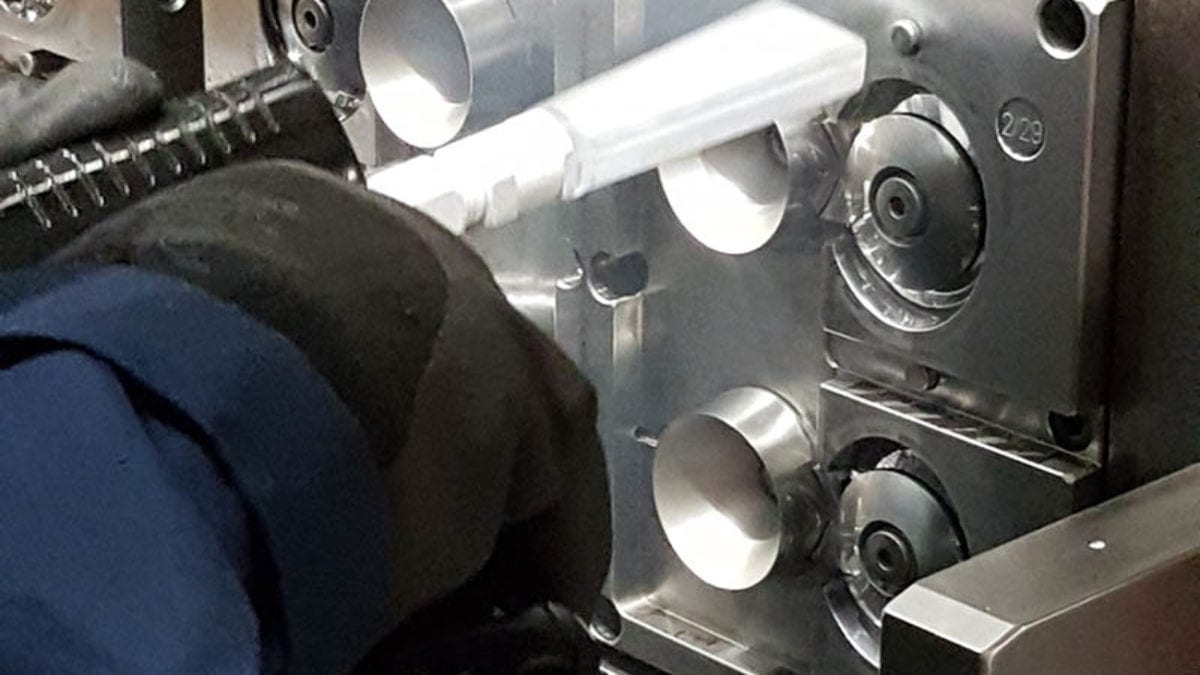

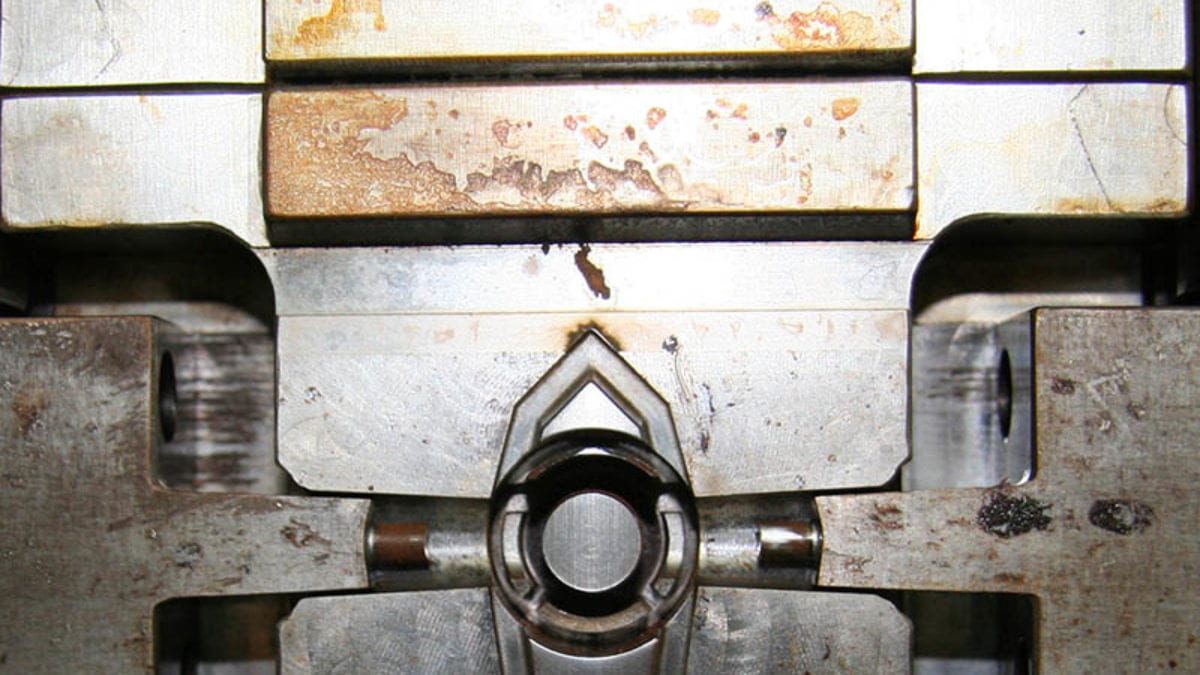

General Equipment Cleaning

Reduce cleaning time and production

downtime while prolonging life of equipment

BENEFITS

Dry ice cleaning quickly and effectively cleans production equipment without water, chemicals or secondary waste.

- Reduce cleaning time

- Eliminate manual cleaning with harmful chemical solvents

- Non-conductive cleaning process

- No secondary waste

- Non-abrasive

Eliminate wear and tear on machinery - Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

- Clean in-place

No disassembly required - Enhance Total Productive Maintenance (TPM) programs

SPECIFIC USE CASES:

- Fin cleaning and inspection

- Turbine engine nacelles

- Electronic components

- Compressor blades

- Brake assemblies

- Foam insulation

- Cargo bay areas

- Turbine engine components

- Tow hitches

- Landing gear systems

- Engine bay covers

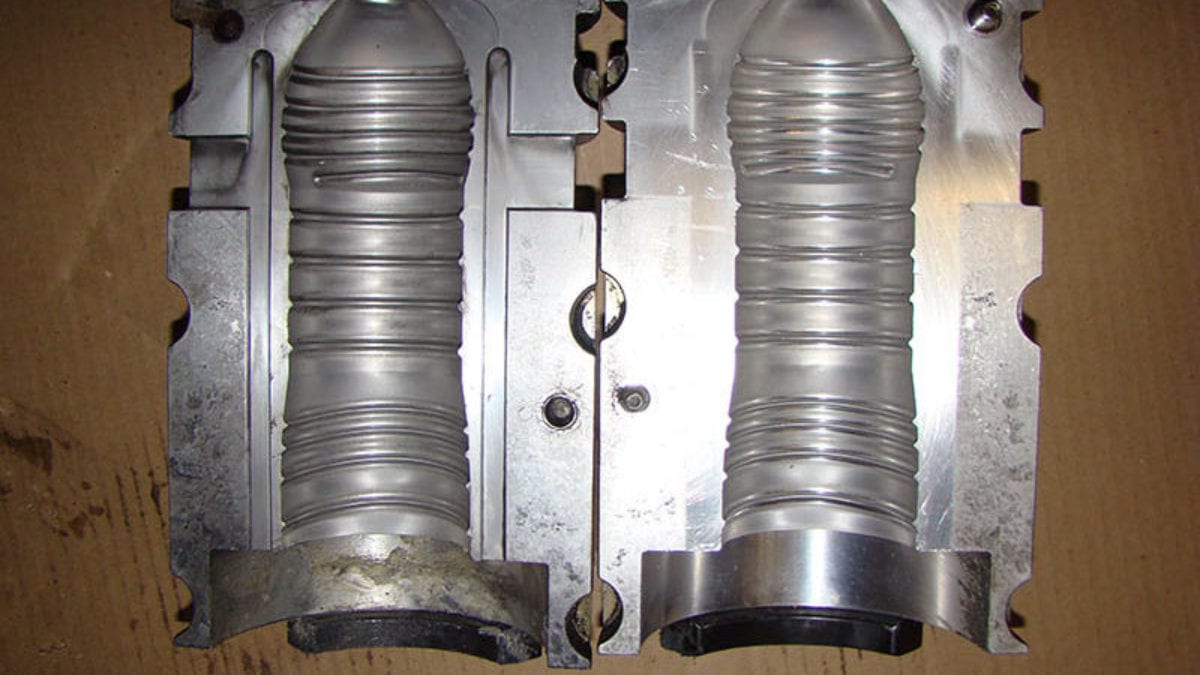

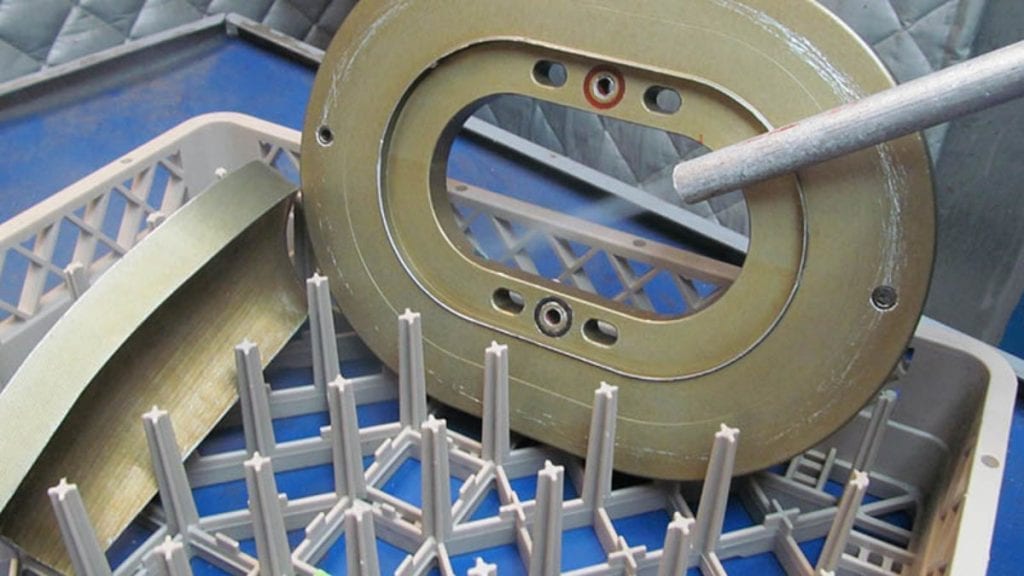

Mould Cleaning

Improve productivity by reducing downtime

BENEFITS

Dry ice blasting is a non-abrasive method that safely cleans moulds online, at operating temperatures.

- Improve product quality

- Clean in-place

Little to no disassembly required - Non-abrasive

No damage to moulds - Reduce scrap

Cleaner moulds lead to higher quality - Meet stringent industry demands

6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance) - Reduce production downtime

Clean quicker and without cooldown or disassembly - Decrease cleaning time and labour costs

- Eliminate painstaking manual cleaning

SPECIFIC USE CASES:

- Injection moulds

- Blow moulds

- Compression moulds

- Urethane moulds

- Textured moulds

- Slush moulds

- Technical moulds

- Extrusion dies

- Rotational moulds

- LSR and LIM moulds

- Thermoform moulds

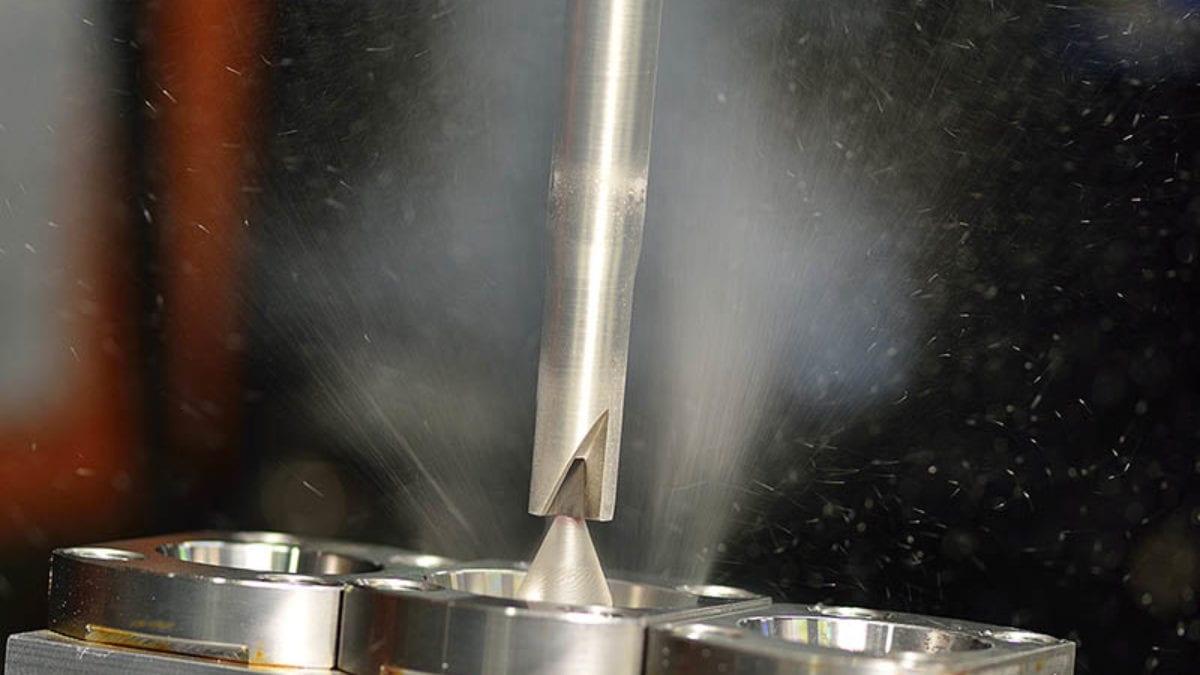

Composite Tool Cleaning

Meet stringent industry demands while

protecting delicate tool surfaces and finishes

BENEFITS

Dry ice blasting quickly cleans a variety of tooling made of a varying degree of materials.

- Reduce production downtime

- Maximise tooling life

- Environmentally responsible

No secondary waste - Reduce cleaning time and labor costs

- Non abrasive

No damage to tooling surfaces - Clean a variety of materials with a single machine

- Clean tooling in place

- Eliminate chemicals and solvents

SPECIFIC USE CASES:

- Compression moulding

- Resin transfer moulding

- Extrusion

- Pre-pregging

- Wet-layup

- Teflon-coated tools

- Highly-polished tools

- Post-processing equipment

- Autoclave flooring walls

- PEEL, Kevlar, E-Glass, S-Glass, Spectra, Boron, Pultrusion, etc.

- LIM moulding

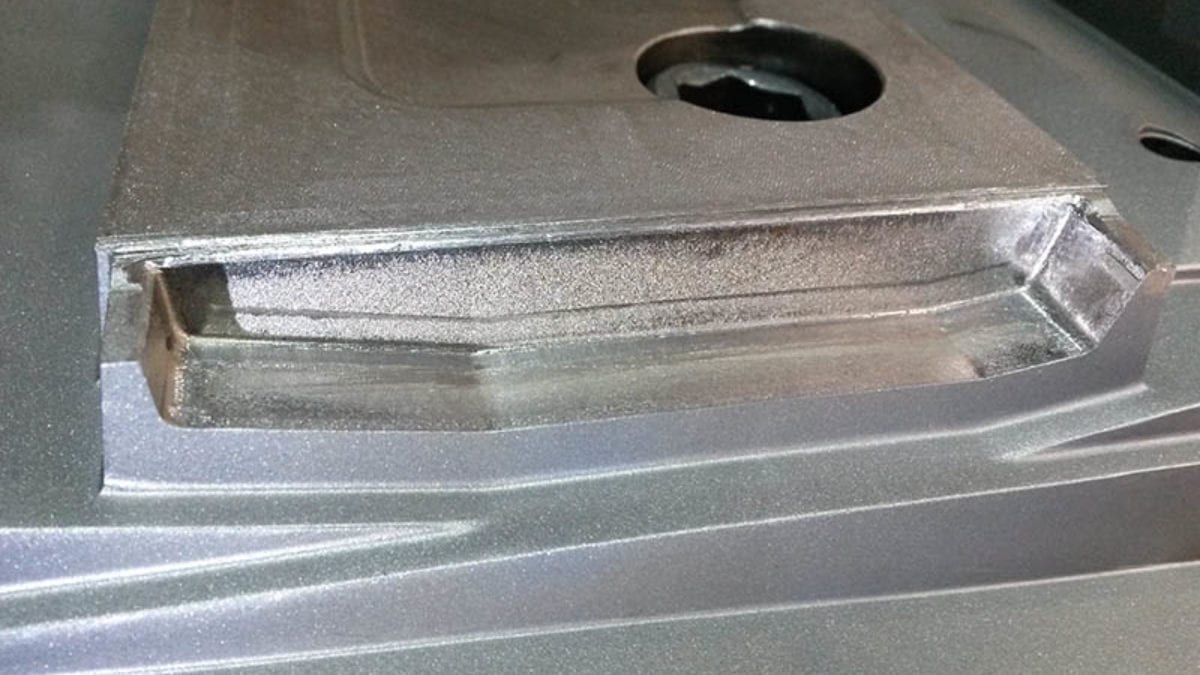

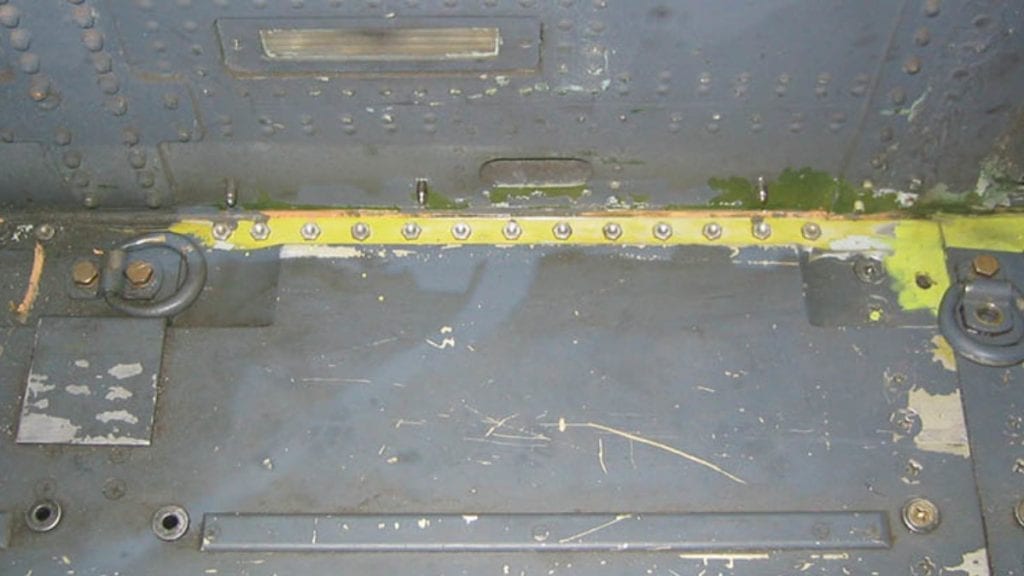

Surface Preparation

Prepare surfaces with a dry process that allows

for immediate coatings/paint application

BENEFITS

Dry ice cleaning is a dry process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate paint or coating after cleaning

- No secondary waste

Reduce disposal costs - Non-abrasive

Will not damage parts - Improve product quality

- Environmentally responsible

SPECIFIC USE CASES:

- Interior parts

- Exterior parts

- Cleaning surfaces before RTVs

BENEFITS OF DRY ICE BLASTING

Reduce cleaning time and costs

while protecting surfaces of

valuable tooling and equipment

Dry ice blasting is used to clean a variety of materials from tooling and equipment, including sealants and adhesives, foam insulation, grease and burnt carbon, carbon fiber residue, plasma overspray, ceramic matrix composites (CMC) residue, release agents and more.

→ Decrease cleaning time and labour costs

→ Non-abrasive

No damage to substrates

→ Clean in-place

No disassembly required

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream