DRY ICE FOR MEDICAL PURPOSES

Medical dry ice can be utilised in a variety of applications. Between cleaning of medical device equipment, refrigeration and storage of biological samples and using dry ice technology to safely remove skin imperfections, dry ice is an important and versatile resource for the medical industry.

At Cold Jet Australia, we support the medical industry with leading dry ice technology and solutions. We deliver the highest density dry ice, allowing for superior medical and pharmaceutical cooling, processing and storage. Our exceptional dry ice blasting solutions have also been utilised to safely and effectively clean manufacturing equipment specifically designed for medical devices.

Dry ice provides a number of beneficial properties that are of great use to medical devices, medical practices and medical purposes. At Cold Jet Australia, we frequently supply high-quality dry ice solutions for those operating in the medical field.

Due to the cold temperatures of dry ice and the fact that dry ice does not leave behind any residue, the solution is ideal for medical device equipment cleaning and medical sample refrigeration. A key component of the cold chain process, dry ice is also said to be a critical factor in the transportation of the COVID-19 vaccine. Learn more about medical dry ice & how Cold Jet support the medical field with dry ice technology below.

Medical Dry Ice Refrigeration

One of the most interesting uses for medical dry ice is refrigerant. Dry ice can potentially be used to transport organs, biological samples, pharmaceuticals and vaccines, ensuring that each material is kept at particular temperatures. Dry ice has been determined as safe for the refrigeration and cooling of pharmaceutical and medical sample storage. Due to the low temperature and control of dry ice blasting equipment, dry ice can also be used by medical professionals to freeze and remove warts or other skin imperfections. Cold Jet Australia can provide refrigerant cooling with our leading high-density dry ice storage.

However, the most common use for dry ice for medical purposes is to safely, effectively and efficiently clean medical device manufacturing equipment. Medical devices need to be designed and manufactured with precision. Dry ice blasting practices work to efficiently and effectively clean medical device manufacturing equipment, to ensure seamless operation.

Speak to a Dry Ice Technician Today

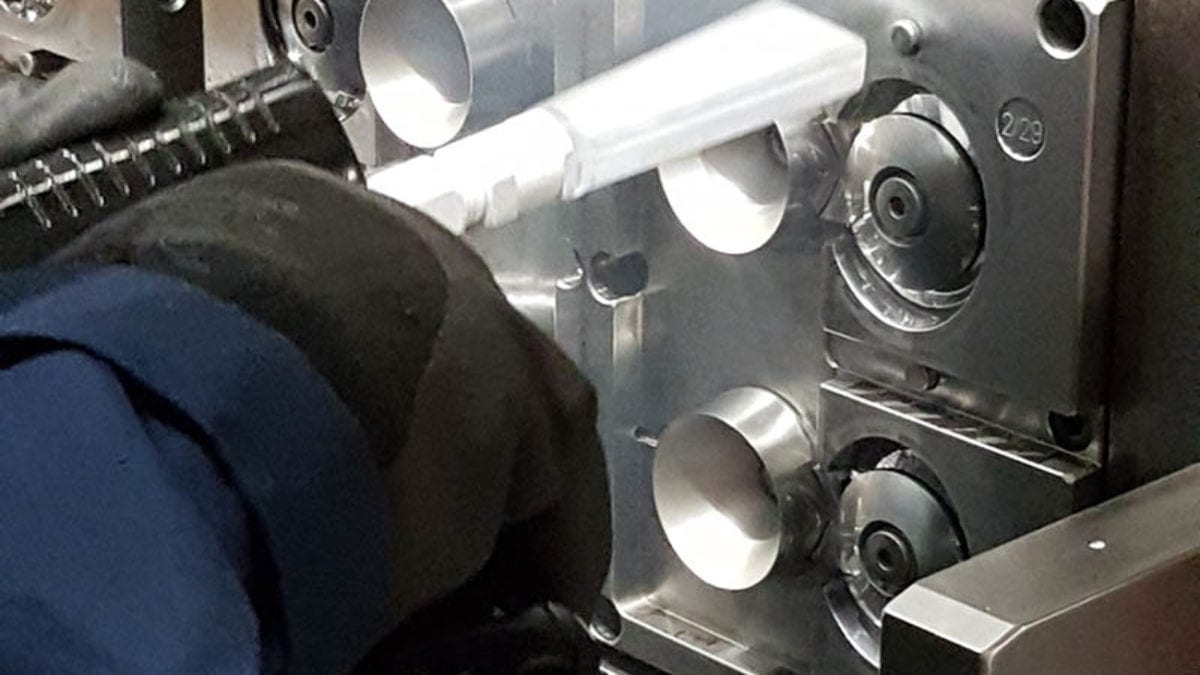

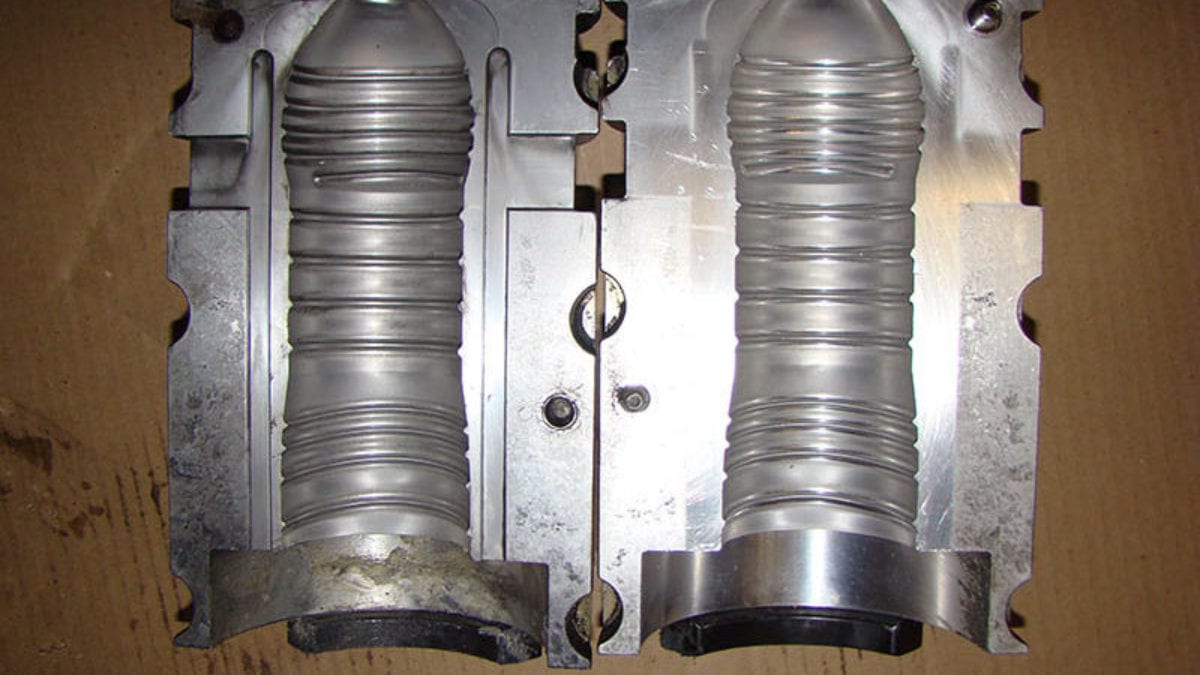

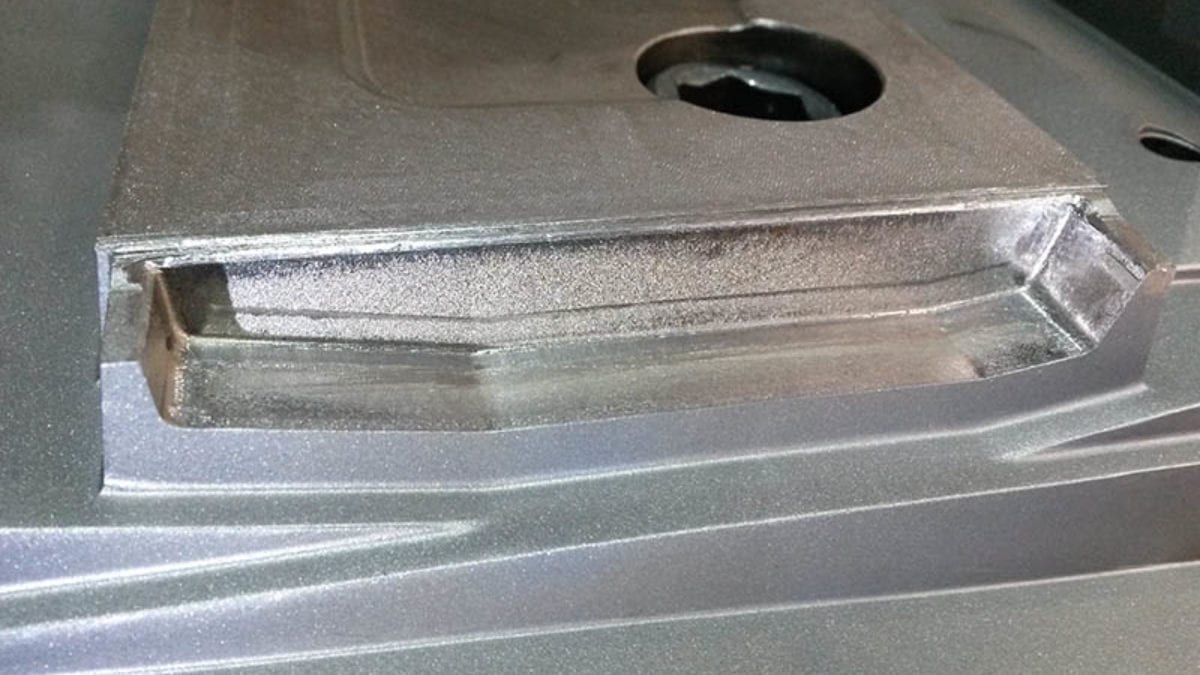

Mould Cleaning for Medical Devices

Dry ice can be used to safely and effectively clean medical device manufacturing equipment.

- Improve product quality

- Clean in-place

- Little to no disassembly required

- Non-abrasive

- No damage to moulds

- Reduce scrap

- Cleaner moulds lead to higher quality

- Meet stringent industry demands

- 6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance)

- Reduce production downtime

- Clean quicker and without cooldown or disassembly

- Decrease cleaning time and labour costs

- Eliminate painstaking manual cleaning

SPECIFIC USES:

- Injection moulds

- Blow moulds

- Compression moulds

- Urethane moulds

- Textured moulds

- Slush moulds

- Technical moulds

- Extrusion dies

- Rotational moulds

- LSR and LIM moulds

- Thermoform moulds

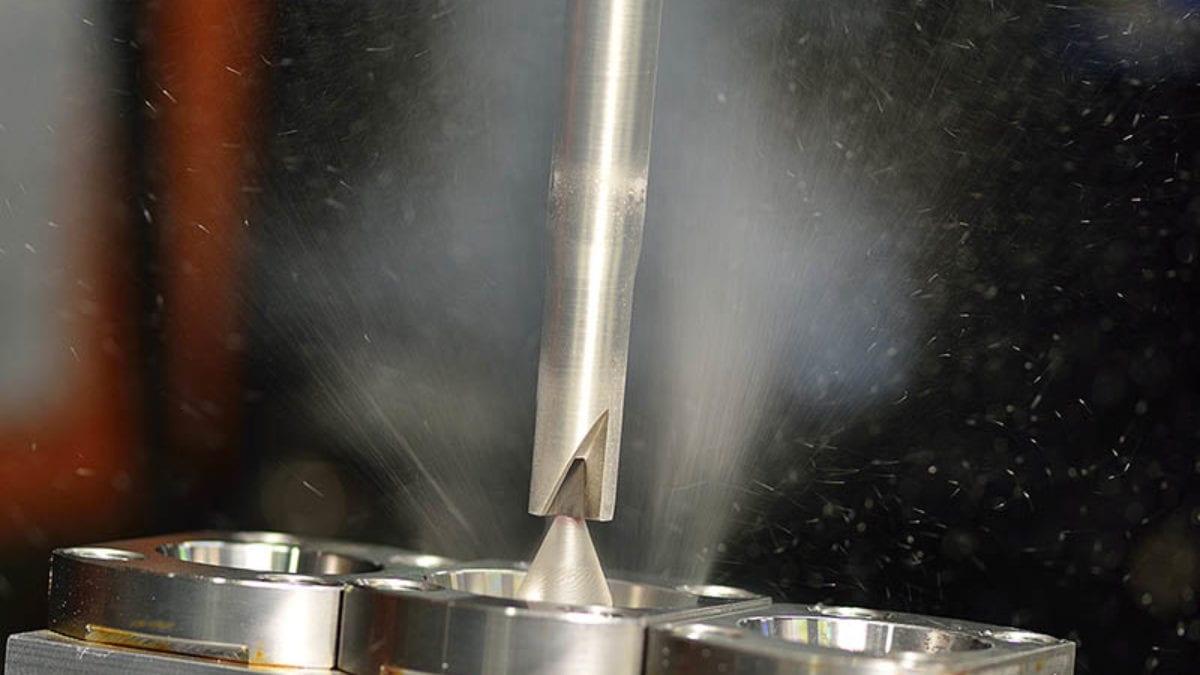

Parts Finishing Cleaning

Quickly and safely deburr and deflash parts of medical devices

- Faster and more uniform clean

- Elimination of cross-contamination

- Non-abrasive

- Lower scrap rates

- Reduce cleaning costs and overall downtime

- Higher quality parts

- Eliminate manual cleaning

SPECIFIC USES:

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- ABS

- UHMWPE

- Nitinol

Why Use Dry Ice for Medical Device Manufacturing Cleans?

Meet stringent industry process demands for quality and consistency

→ Decrease cleaning time & labour costs

→ Non-abrasive

→ Clean in-place

→ Increase productivity & reduce downtime

→ Non-conductive cleaning process

→ Employee safe

→ Environmentally responsible

→ Improve part quality & reduce scrap

→ No secondary waste stream

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

Medical Dry Ice

Frequently Asked Questions

What Is Dry Ice?

Dry ice is the solid form of carbon dioxide. Commonly used as a cooling agent, dry ice has a lower temperature than water ice and does not leave any residue when it disappears. Dry ice is colourless, non-flammable, and can have a zesty odour and can lower the pH of a solution when dissolved in water.

Dry ice typically comes in blocks or pellets to be utilised as you desire. For medical dry ice refrigerants, you may consider blocks of dry ice. If you require dry ice for dry ice blasting equipment, you should be looking at 3mm dry ice pellets.

How Cold Is Dry Ice?

Very!

Dry ice is solid carbon dioxide. The surface temperature of dry ice is -78.5°C (-109.3°F). A frozen block of dry ice transforms directly into a gas at this temperature, skipping the liquid phase entirely.

Due to the extremely cold temperatures of dry ice, severe cold burns can occur with prolonged direct contact with skin (hence why it can often be used by medical professionals to safely remove and freeze warts). Dry ice must be handled with special equipment to ensure that skin to skin contact does not occur.

Who Requires Dry Ice Production?

Dry ice production is typically utilised by those who require refrigeration and cooling items to prevent spoiling or damage. The most common example of this is the preservation of food, beverages and other samples, using non-cyclic refrigeration. These are the main applications that we deliver dry ice production services for:

- Medical Industry

- Airline Catering

- Cold Chain Management

- Food Processing Cooling

- Medical and Pharmaceutical Shipment Cooling

- Production for Blasting

- Production for Resale

Which Other Industries Do Cold Jet Work With?

Cold Jet work with a wide scope of industries across Australia and the world. Our diverse client background means that we can customise dry ice solutions to meet a wide variety of applications beyond medical dry ice. The main industries that we engage with include:

- Aerospace and Aviation

- Automotive

- Contract Cleaning

- Engineered Wood

- Food and Beverage

- Foundry

- Medical

- Mining

- Oil and Gas

- Packaging

- Plastics and Composites

- Power Generation

- Printing

- Public Transportation

- Restoration and Remediation

- Rubber and Tires

- Textiles

Can’t see your industry? Don’t stress. This is just a primary selection of the industries that we typically service. Contact our friendly team of technicians, and we’ll let you know if we can provide a dry ice solution for you and your project.

Why Choose Cold Jet For Dry Ice?

As one of Australia’s longest-running providers of dry ice, we really are the experts when it comes to the various solutions for dry ice for medical puposes. Cold Jet are a leading dry ice company that prides itself on its exceptional services and products. We are passionate about dry ice and using our state-of-the-art dry ice technologies to provide expert solutions. Our experienced, knowledgeable and friendly Australian team will always go above and beyond to ensure your needs are both met and exceeded.

If you have any questions, queries, or would like to talk to one of our dry ice technicians, get in touch today to learn more about what our dry ice technology can do for you.

MEDICAL DEVICE DRY ICE CASE STUDY

Ready to speak to a dry ice technician?