DRY ICE BLASTING APPLICATIONS:

Dry Ice Remediation

Looking for expert dry ice blasting remediation services? You’ve come to the right place. Cold Jet are the dry ice specialists in Australia and provide leading remediation solutions with the use of safe, reliable and efficient dry ice blasting technology. Whether it be for fire and smoke restoration, soot removal, mould and bacteria remediation or extensive moisture damage, dry ice cleaning will effectively remediate all areas of the space.

Dry ice blasting is an innovative, effective and environmentally friendly solution for remediation efforts. When compared to alternative cleaning and remediation methods, dry ice cleaning comes out far more efficient, timesaving, cost-effective and powerful.

Dry ice pellets are accelerated at the affected areas of damage, where the solution is sublimating on impact; resulting in an effective clean, with no residue or waste produced. The low temperature and powerful impact of dry ice mean that all contaminants (soot, smoke, mould etc.) are lifted from the surface, without further damaging any materials. The end result of dry ice remediation is the affected materials being restored back to their original state.

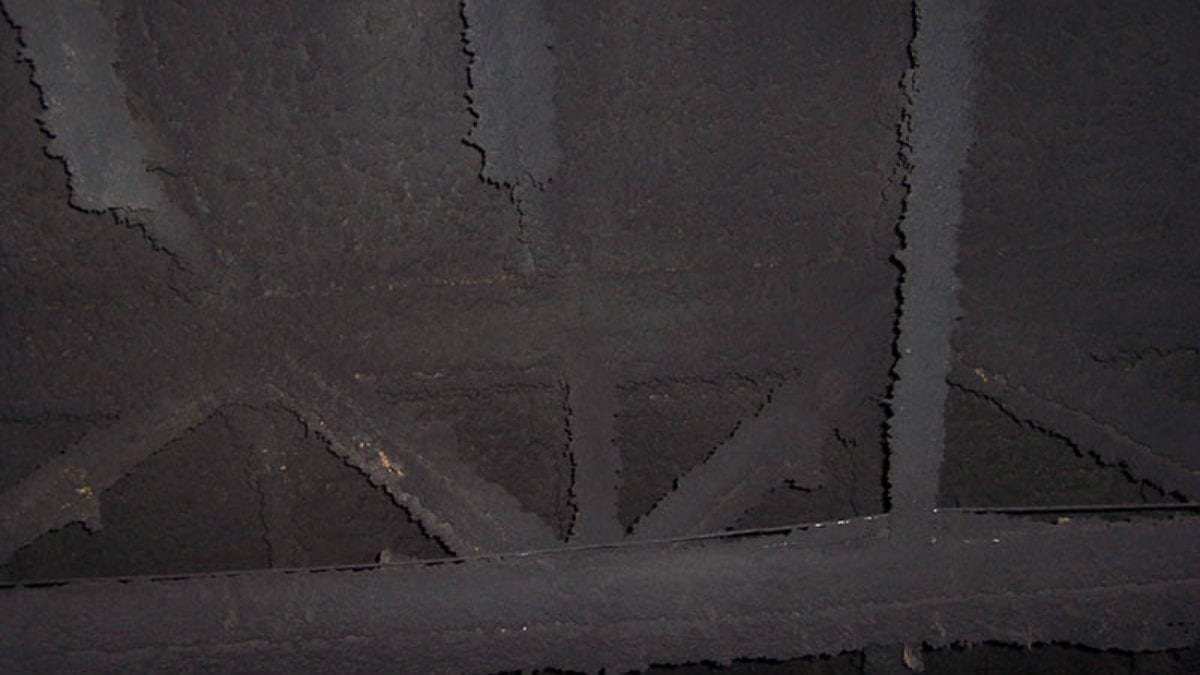

Dry ice blasting is one of the most effective ways to remediate and restore damage caused by fire, smoke, soot or moisture. Dry ice can effectively restore wood, concrete, brick and other building materials, removing and deodorising soot, smoke, mould and bacteria growth.

Speak to a Dry Ice Remediation Expert Today

SPECIFIC USES

Dry ice blasting produces better results in a wide range of remediation projects

- Fire, soot and smoke remediation

- Mould remediation

- Water and flood remediation

- Odour elimination

RELATED INDUSTRIES

Dry Ice Remediation for Fire, Smoke & Water Damage

Dry ice blasting has been proven to be a faster and more effective solution in remediation efforts. The process eliminates manual cleaning and does not produce secondary waste, which reduces the amount of time spent on encapsulation and waste collection and disposal. Dry ice is an effective solution for the safe remediation of fire damage, smoke damage, water damage and soot deodorisation.

Dry ice blasting can access and clean hard to reach areas, such as the tight angles of trusses, around nails, wiring and all plumbing without damage to the surface integrity. The process also significantly reduces odour created by fire, smoke and mould damage.

→ Reduced remediation time

Remove contaminants faster and more effectively

→ No secondary waste

Reduce encapsulation and disposal costs

→ Non-abrasive

Will not damage sensitive or delicate surfaces

→ Chemical free process

Eliminate abrasive and harmful chemicals

→ Eliminate manual cleaning

Reduce labor costs and project time

→ Environmentally responsible

Will not harm surrounding areas

→ 99% mould spore removal on wood

When IAQA standards are followed

→ Dry cleaning process

No added moisture

→ Ability to deodourise affected areas

Remove odour created by mould and smoke damage

How Does Dry Ice Remediate Surfaces?

Dry ice blasting safely cleans fire, water and soot damage without causing erosion and etching that is typical of abrasive cleaning methods. The low temperature of dry ice, in combination with the powerful force of the pellet blasting, work to break the bonds between the surface and the contaminants from fire, water and soot damage. There are no chemicals used, no liquids, and no waste generated.

Dry ice remediation results in a surface that is clean, free from contaminants and returned to its original state. Dry ice remediation does not produce any moisture or residue, meaning it is safe for electrical components and will not cause any water damage. Dry ice blasting can clean concrete, wood, brick and other building materials, also eliminating the smell and odours associated with fire, water and smoke damage.

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

Frequently Asked Questions

Between our dry ice remediation, dry ice production services and our exceptional dry ice machinery, we’re the experts in dry ice offerings in Australia. We’re renowned for providing dry ice with the highest density, and we’re extremely proud of that. Striving to deliver the highest quality services and products, Cold Jet are committed to maintaining an exceptional standard, including with all customer service interactions for fire, water and smoke remediation with dry ice.

As such, we’ve put together a ‘frequently asked questions’ section to answer all common questions to do with dry ice blasting remediation services.

How Does Dry Ice Work for Remediation?

There are three primary factors that contribute to the dry ice remediation process. The factors include Pellet Kinetic Energy, the Thermal Shock Effect, and the Thermal-Kinetic Effect. In order to better understand the cleaning practice, the process can be broken down into three stages – Impact, Cold, Expansion (ICE).

IMPACT – The impact of pellets creates a kinetic energy effect. The soft dry ice accelerated by compressed air at supersonic speeds.

COLD – The cold temperature of dry ice creates a thermal effect. The low temperature of dry ice (-78.9°C /-109°F) causes the bond to break between the contaminant (soot, bacteria, moisture damage) and the surface.

EXPANSION – The expansion of the dry ice pellets. Dry ice pellets sublimate on impact, expanding in size and removing the contaminants.

Why Are the Advantages of Using Dry Ice?

Dry Ice Is Eco-Friendly

Using our technology for dry ice blasting for remediation, dry ice is much more sustainable than other cleaning methods. Our equipment utilises materials that are inert, non-conductive and non-corrosive. There is no secondary toxic waste, moisture, or residue produced when using our dry ice blasting methods. As such, our methods do not produce any harmful chemicals or hazardous waste. What’s more, the dry ice used for fire, moisture and smoke remediation is made from reclaimed CO2 and does not add any additional CO2 into the atmosphere.

Dry Ice Eliminates Pollutive Secondary Waste

When the dry ice impacts the surface being cleaned, it sublimates – turning directly from a solid to a gas—and thus does not produce secondary waste. Similar cleaning techniques leave behind a residue that must be cleaned up afterwards, along with the offending contaminant. This media can become hazardous and create downstream contamination and harm the surrounding area and installations. Say goodbye to secondary wastes with dry ice blasting for fire restoration and water remediation.

Dry Ice Blasting Remediation Is Safe

Dry ice manufacturing, production and blasting for cleaning is safe, as it relies purely on carbon dioxide. The process of dry ice blasting is non-toxic and non-flammable. In fact, dry ice is so safe that the use has been approved for commercial use around food by the EPA, FDA and USDA. With a qualified professional, dry ice blasting for remediation is one of the safest cleaning options.

Dry Ice Blasting Saves Time

Dry ice blasting, particularly for fire and moisture remediation, is incredibly time-efficient when compared to other cleaning methods. Dry ice blasting offers a significantly faster process that leads to minimised downtime and an increase in productivity. A reduction in labour and the lengthy processes that typically come with remediation mean that dry ice blasting remediation is incredibly time saving and efficient.

What Else Can Dry Ice Be Used For?

In the case of dry ice remediation, the technique is extremely effective for the removal of fire, water, soot, mould and smoke. Due to the plethora of benefits of using dry ice blasting, the practice can also be used for a wide range of applications, including:

- Coating & Corrosion Removal

- Composite Tool Cleaning

- Core Box Cleaning

- Equipment Cleaning

- Historical Restoration

- Adhesive removal

- Part Finishing

- Surface preparation

- Surface Preparation

- Rust Removal

- Weld Line Cleaning

- Dry Ice Manufacturing for Airline Catering

- Dry Ice Cooling in Food Processing

Why Choose Cold Jet for Remediation Dry Ice Blasting?

As one of Australia’s longest-running providers of dry ice solutions, we really are the experts when it comes to dry ice remediation. We’re an Australian owned, reliable and reputable dry ice company that prides itself on its exceptional services and products. We are passionate about dry ice blasting for fire and water remediation and using our state-of-the-art dry ice technologies to provide solutions. Our experienced, knowledgeable and friendly Australian team will always go above and beyond to ensure your required needs are both met and exceeded.

If you have any questions, queries, or would like to talk to one of our dry ice specialists, please do not hesitate to get in touch today. Talk to our expert technicians to learn more about what our dry ice technology can do for you.