DRY ICE BLASTING APPLICATIONS:

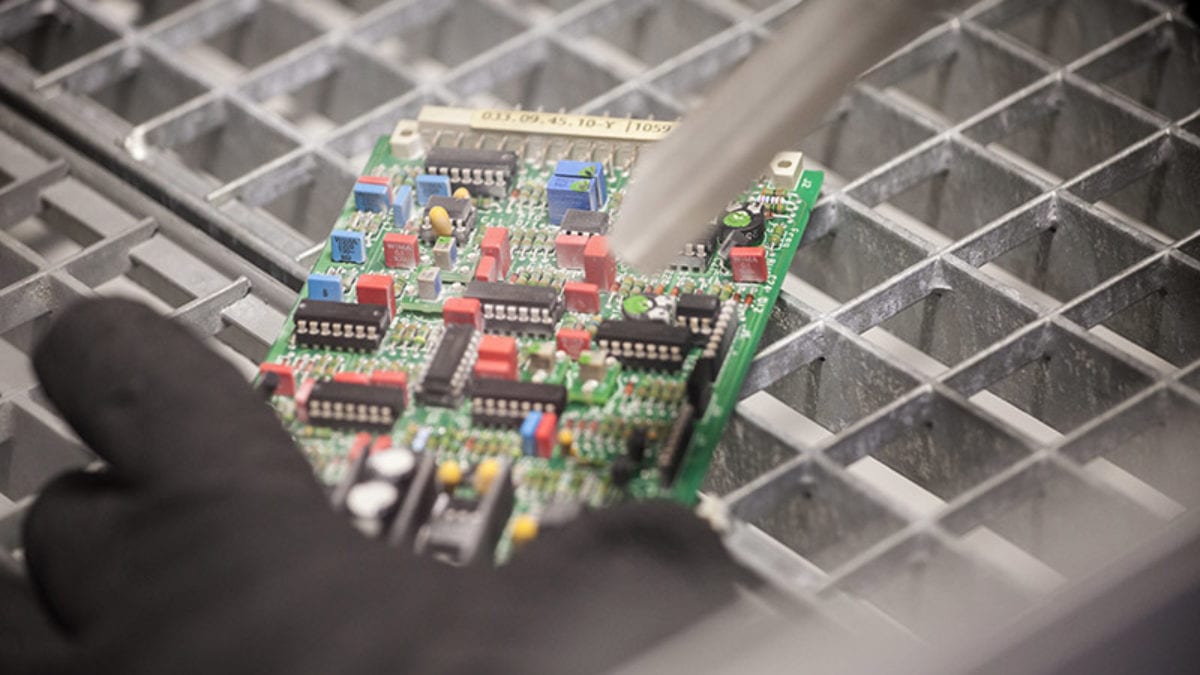

Dry Ice General Equipment Cleaning

Looking for a way to safely and reliably clean your industrial equipment? Cold Jet can help. Australia’s leader in the dry ice market, we provide expert solutions for your industrial equipment, including dry ice cleaning. Dry ice cleaning for general equipment is the ideal solution for a wide range of industries and machinery – dry ice is efficient, effective and will not damage any materials or surfaces.

Cold Jet’s breadth of experience in the dry ice cleaning industry means that we’re able to provide tried and tested, tailored solutions for a wide range of industrial applications. Working with foundries, automotive workshops, restoration teams, and printing factories, we can adapt our dry ice cleaning to meet each piece of equipment’s unique demands.

Dry ice blasting utilises CO2 to deliver a powerful, effective clean, removing all contaminants and protecting surfaces. With each industrial equipment piece, we’ll make sure there are no risks of damage and that your machinery is left sparkling clean. Do you need to a gentle, more precise clean on your technical parts? Or are you after a more aggressive clean and contaminant removal? We can tailor our dry ice cleaning to meet the needs of your specific equipment.

Dry ice cleaning provides a deeper clean for your equipment, with no waste. Extremely effective, reliable and safe for commercial and industrial use, the benefits of using dry ice for cleaning equipment are plentiful. The most prominent advantage for general equipment cleans; however, has to be the fact that there is no moisture and no residue.

Effectively clean your equipment & improve your operations with dry ice

Dry ice blasting cleans all types of production and ancillary equipment without damaging surfaces, creating secondary waste or harming employees or the environment. From technical industrial parts to large, corroded pieces of machinery, dry ice blasting can clean and remove every type of contaminant imaginable. Industrial dry ice cleaning does not just remove the dirt, dust and grime from your equipment – dry ice works to ensure your equipment operates seamlessly.

Speak to a Dry Ice Expert Today

SPECIFIC USES

Dry ice blasting is an effective cleaning solution for all types of equipment and tooling

- Production equipment

- Ceilings and walls

- Equipment degreasing

- Surface cleaning before painting

- Forklifts

- Electric motors

- Electrical boxes

- Control panels

- Pipes, hoses and fittings

- Conveyors

- Cooling fans

- Hydraulic parts

- Robotics

- Sanding belts

How Does Dry Ice Blasting Work?

There are three primary factors that contribute to the dry ice equipment cleaning process. The factors include Pellet Kinetic Energy, the Thermal Shock Effect, and the Thermal-Kinetic Effect. In order to better understand industrial dry ice cleaning, the process can be broken down into three stages – Impact, Cold, Expansion (ICE).

IMPACT – The impact of pellets creates a kinetic energy effect. The soft dry ice accelerated by compressed air at supersonic speeds.

COLD – The cold temperature of dry ice creates a thermal effect. The low temperature of dry ice (-78.9°C /-109°F) causes the bond to break between the contaminant and the surface.

EXPANSION – The expansion of the dry ice pellets. Dry ice pellets sublimate on impact, expanding in size and removing the contaminants.

→ Superior clean

Clean more effectively than with traditional methods

→ Clean in-place and online

Reduce cleaning time and resulting downtime

→ Non-abrasive

No risk of damaging equipment

→ Increase operational efficiency

More efficiently allocate labor

→ Environmentally responsible

Eliminate chemicals or secondary waste streams

→ Enhance operator safety

Eliminate manual cleaning and exposure to unsafe conditions

→ Improve part quality and reduce scrap

Clean more often, resulting in high quality products

→ Non-toxic and non-conductive

→ Access and clean tight spaces

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

Frequently Asked Questions About General Equipment Cleaning

Why Is Dry Ice Ideal for Equipment Cleaning?

Due to the unique characteristics of dry ice, it has many benefits that make it an extremely favourable option when compared to cleaning alternatives. The main benefits of using dry ice for equipment cleaning include, but are not limited to:

- Cleaning equipment in place with little or no disassembly

- Dry cleaning with no water or chemicals

- Reducing downtime associated with cleaning

- Cleaning without secondary waste

- Improving product quality and reducing scrap

- Eliminating equipment wear and tear

- An environmentally responsible cleaning method

Is Dry Ice Harmful to The Environment?

No. Dry ice blasting is the ideal solution for those looking for an environmentally friendly cleaning solution. Here’s how dry ice cleaning is environmentally friendly:

Dry Ice Blasting Eliminates Harmful Secondary Waste

When the dry ice impacts the surface being cleaned, it sublimates – turning directly from a solid to a gas—and thus does not produce secondary waste. Similar cleaning techniques leave behind a residue that must be cleaned up afterwards, along with the offending contaminant. This media can become hazardous and create downstream contamination and harm the surrounding area and installations. Say goodbye to secondary wastes with dry ice blasting for equipment cleaning.

Dry Ice Uses Reclaimed CO2

All dry ice used in the dry ice blasting process for equipment cleaning is made from reclaimed CO2, which is a by-product of other industrial processes. This CO2, which would have otherwise been released into the atmosphere, is captured and given new life as dry ice. Dry ice blasting does not produce or emit additional CO2 into the atmosphere.

Dry Ice Blasting Is Non-Toxic

Dry ice blasting for industrial equipment cleaning is non-toxic and eliminates the need for chemical solvents in industrial cleaning processes. The dry ice used in the dry ice blasting process is a food grade media and is EPA, FDA and USDA approved for use around food manufacturing. It is colourless, tasteless, odourless and non-toxic.

Will Dry Ice Leave Residue on My Equipment?

No – dry ice blasting does not leave residue or waste when cleaning industrial equipment. Dry ice sublimates upon impact with the surface being cleaned, which results in no secondary waste, no residue and no introduction of moisture. This eliminates extra clean-up, disposal of secondary waste streams and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components before cleaning. This significantly reduces the duration of cleaning projects and the resulting shutdowns.

With no secondary waste produced, this also means machinery can be cleaned while online and still operating.

Why Choose Cold Jet for Industrial Dry Ice Cleaning?

As one of Australia’s longest-running providers of dry ice solutions, we really are the experts when it comes to dry ice for equipment cleaning. We’re an Australian owned, reliable and reputable dry ice company that prides itself on its exceptional services and products. We are passionate about dry ice blasting for machinery and using our state-of-the-art dry ice technologies to provide solutions. Our experienced, knowledgeable and friendly Australian team will always go above and beyond to ensure your required needs are both met and exceeded.

Which Industries Use Cold Jet?

At Cold Jet, we’re lucky enough to be able to work with a wide range of industries that require the assistance of dry ice blasting, dry ice cleaning, dry ice production and dry ice manufacturing equipment. Our experts also regularly deliver dry ice training to those who frequently work with dry ice materials.

Covering all aspects of dry ice, we strongly believe that we can provide a solution for almost every industry with our industry-leading technology. Over the years, we have acquired an extensive and diverse portfolio of clients, showcasing our breadth in dry ice solutions. Here are the main industries that we typically work with at Cold Jet:

- Aerospace and Aviation Industry

- Automotive Industry

- Contract Cleaning Industry

- Engineered Wood Industry

- Food and Beverage Industry

- Foundry Industry

- Medical Device Industry

- Mining Industry

- Oil and Gas Industry

- Packaging Industry

- Plastics and Composites Industry

- Power Generation Industry

- Printing Industry

- Public Transportation Industry

- Restoration and Surface preparation Industry

- Rubber and Tires Industry

- Textiles Industry

What Else Can Dry Ice Be Used For?

We know that dry ice cleaning is the ideal solution for general equipment cleaning. But there are so many more uses for this environmentally friendly, efficient and effective solution. Due to the abundance of benefits of using dry ice blasting, the practice can also be used for a wide range of applications, including:

- Adhesive Removal

- Coating & Corrosion Removal

- Composite Tool Cleaning

- Core Box & Mould Casting Cleaning

- Historical Restoration

- Mould removal

- Remediation

- Part Finishing

- Surface preparation

- Surface Preparation

- Weld Line Cleaning

- Dry Ice Manufacturing for Airline Catering

- Dry Ice Cooling in Food Processing