PACKAGING

Clean packaging equipment faster,

in-place and without damage

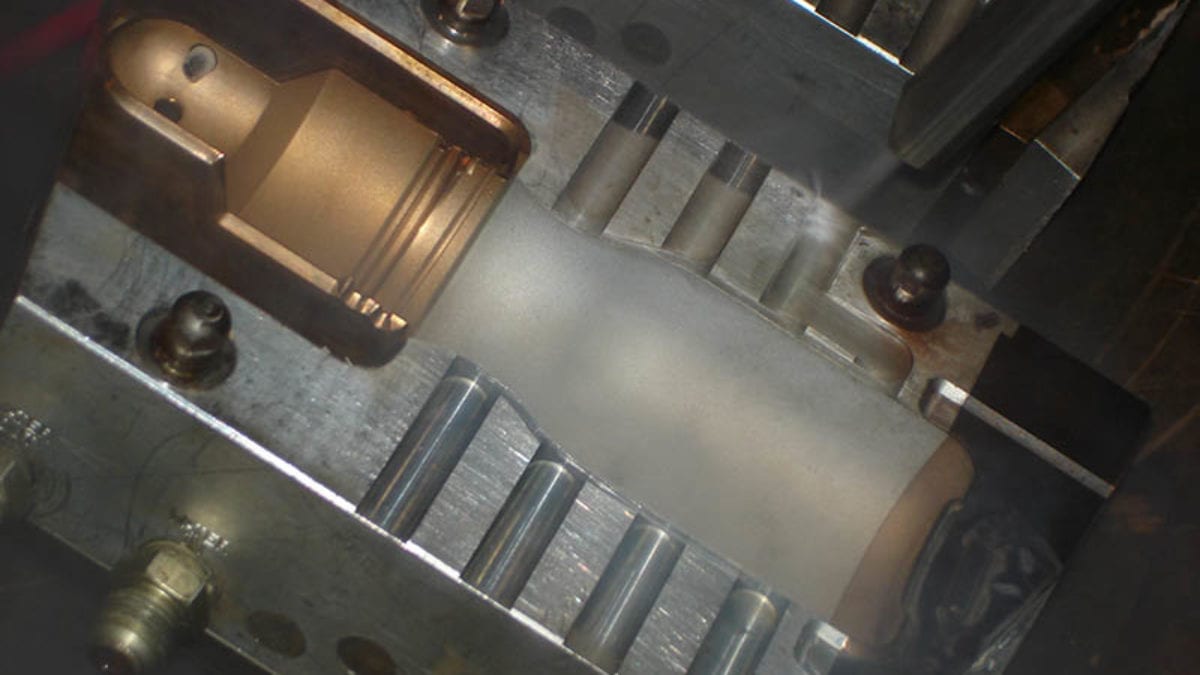

Dry ice blasting thoroughly cleans buildup, such as adhesive, ink, grease,

paper dust, labels and food residue from packaging equipment in-place, while

running, enabling facilities to maximise control and production efficiency.

CASE STUDIES

Revolutionise processes

to drive real results.

Packaging Equipment Cleaning

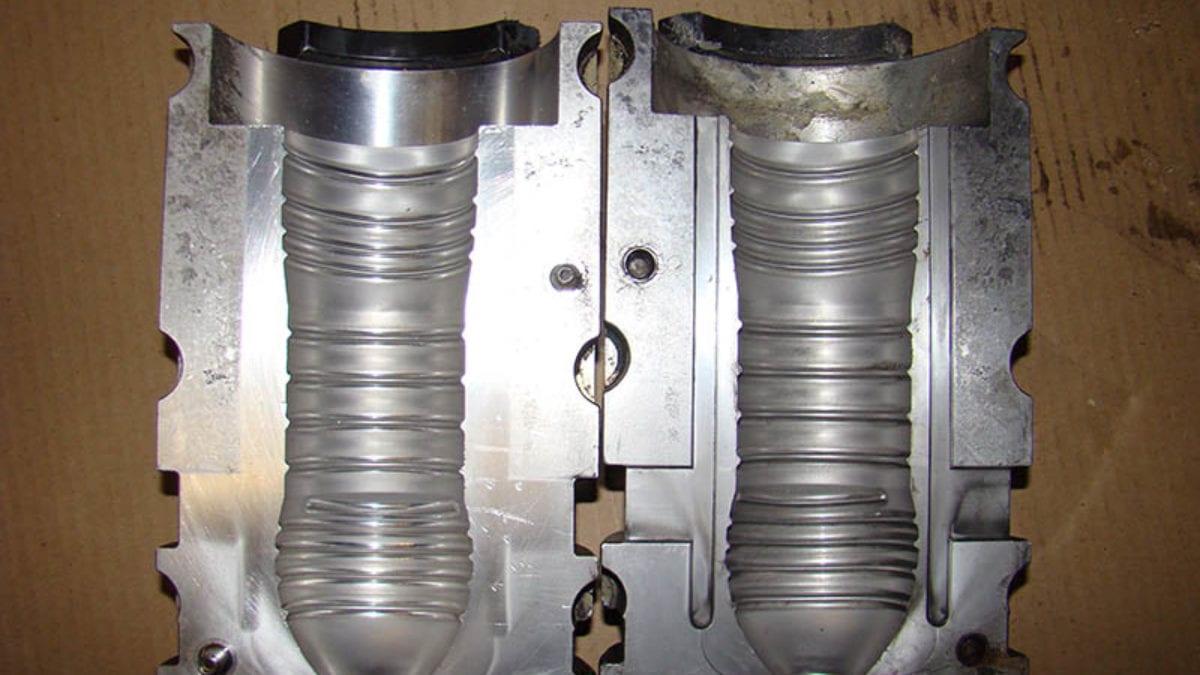

Quickly clean buildup from production

equipment without timely disassembly

BENEFITS

Dry ice cleaning increases productivity by eliminating unpredictable downtime caused by dirty, hard-to-clean packaging equipment.

- Clean hot and online

- Reduce cleaning time and resulting downtime

- Reduce risk of unplanned production stoppages and costly repairs

- Eliminate manual cleaning with harmful chemical solvents, wire brushes and scrapers

- No secondary waste

- Non-abrasive

Clean sensitive equipment without damage - Environmentally responsible

SPECIFIC USE CASES:

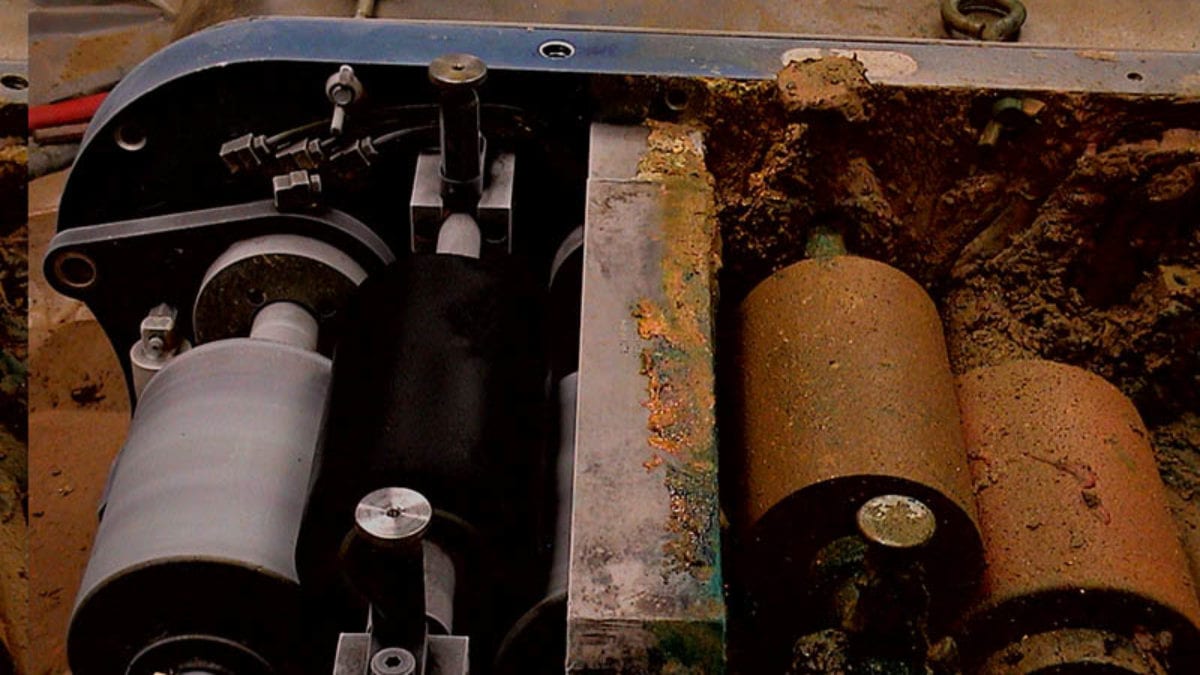

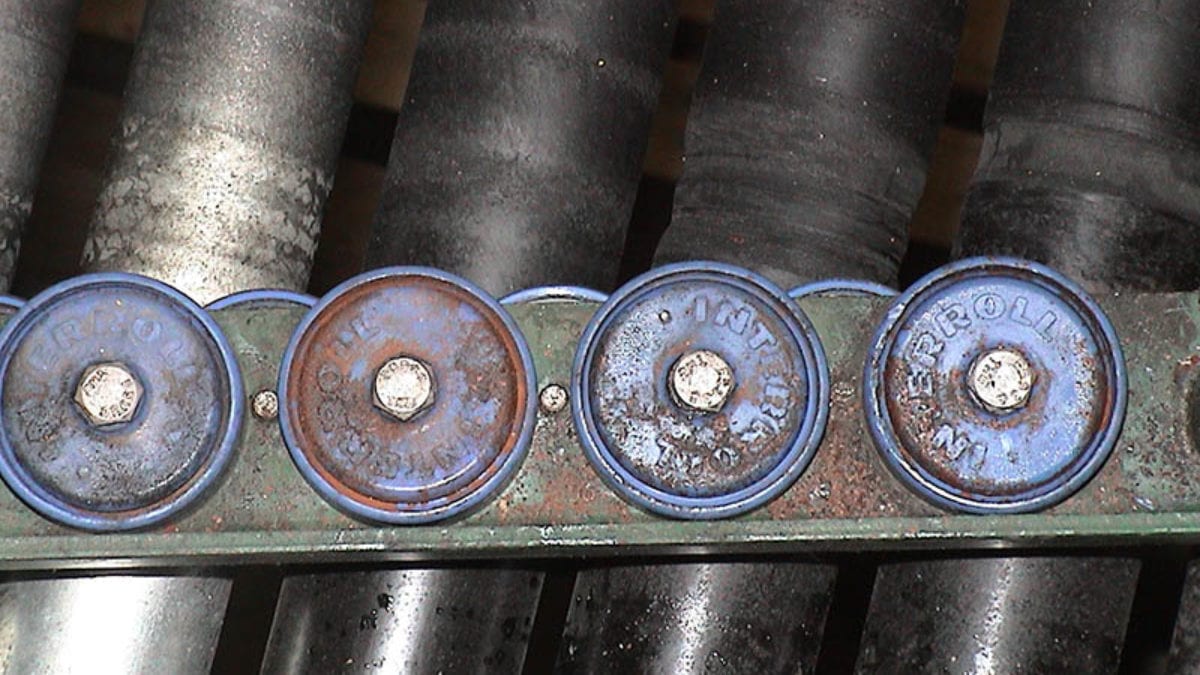

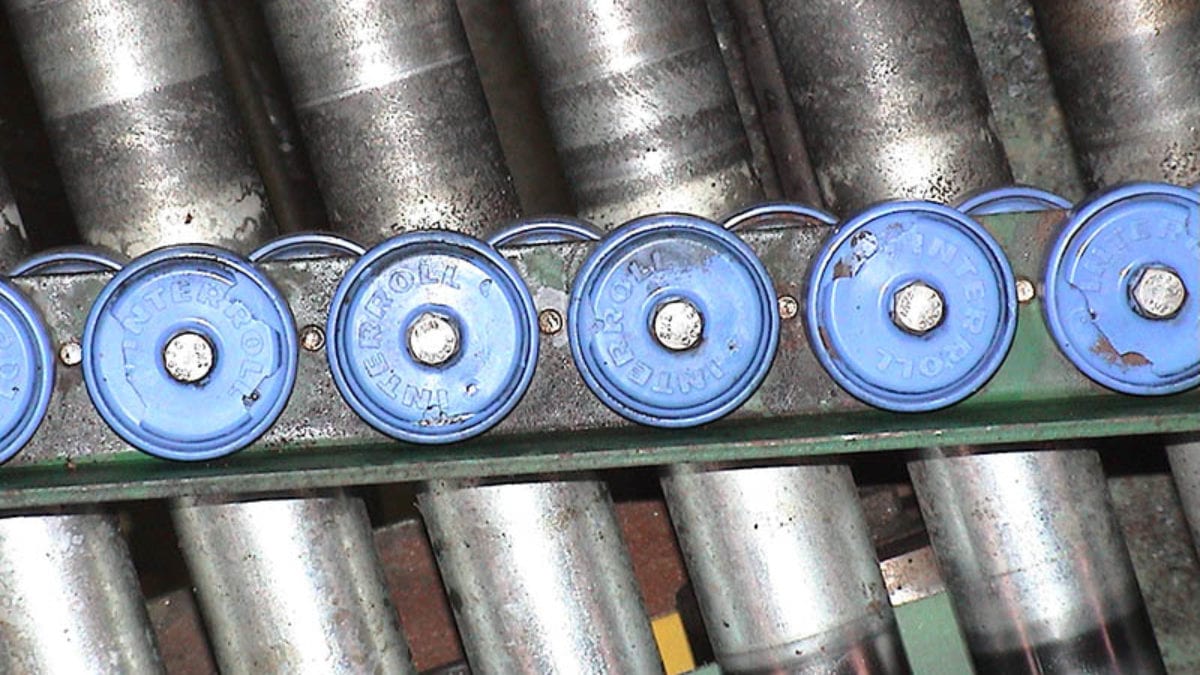

- Conveyors and airveyors

- Rollers and chains

- Baggers

- Pack-off tables

- Bag and box formers

- Glue applicators and labelers

- Tape applicators

- Printers

- Presses and embossers

- Dryers

- Palletizers and de-nesters

- Radial feeders (Ishida weighers)

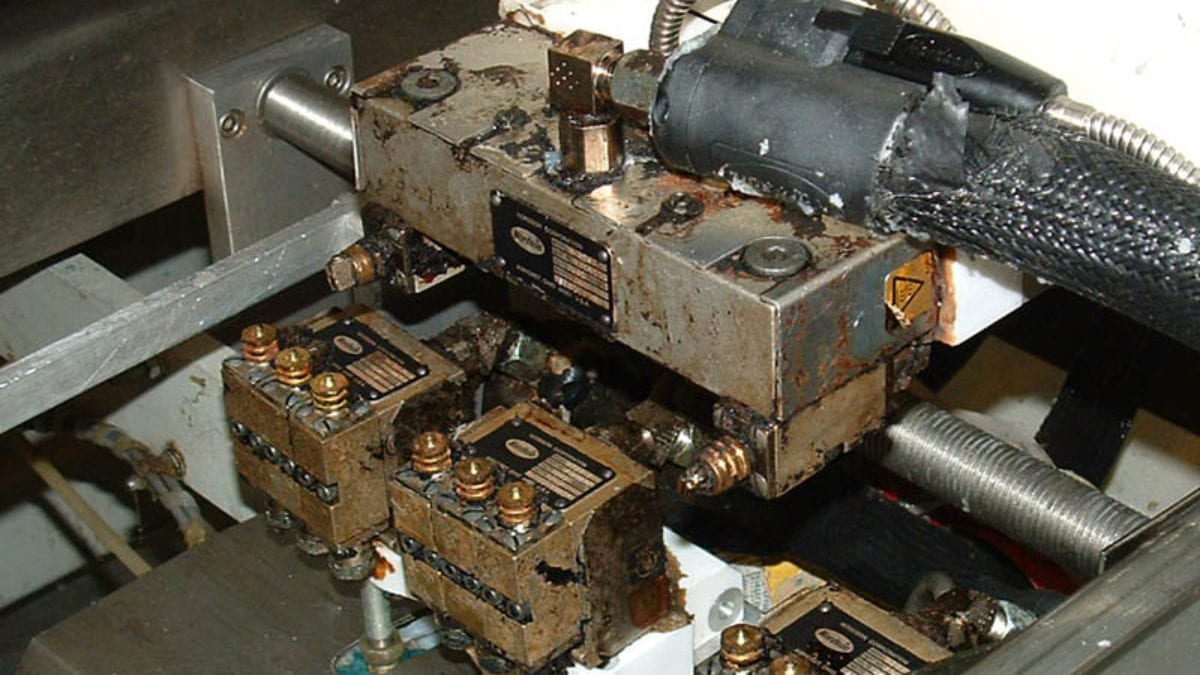

- Electrical components and motors

- Drive Belts

BENEFITS OF DRY ICE BLASTING

Clean predictably and effectively

while reducing downtime,

manual cleaning and scrap rates

Dry ice cleaning provides a quick, safe and economical solution to clean tooling and equipment, resulting in less downtime, a better clean, less rejected parts, improved tool utilisation and longer asset life.

→ Clean online or in place, even while equipment is hot and running

→ Eliminate unpredictable manual cleaning

→ Reduce risk of unplanned production stoppages and costly repairs

→ No water or harmful chemicals

→ Non-conductive

Clean electronics, sensors and motors without damage

→ No secondary waste streams

→ Reduce labour costs

→ Reduce scrap rates

→ Environmentally responsible