FOUNDRY

Reduce downtime while protecting

foundry equipment from damage

Dry ice blasting significantly reduces cleaning time of permanent moulds, core

boxes, die cast tooling and ancillary equipment while improving part quality.

CASE STUDIES

Revolutionise processes

to drive real results.

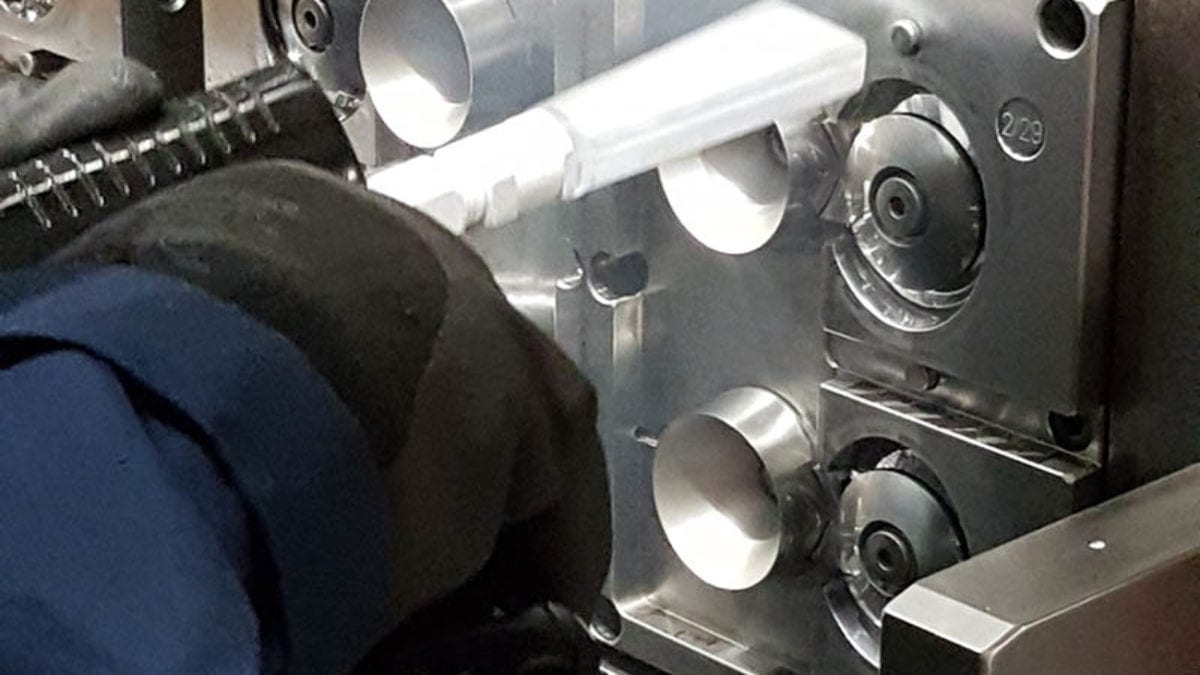

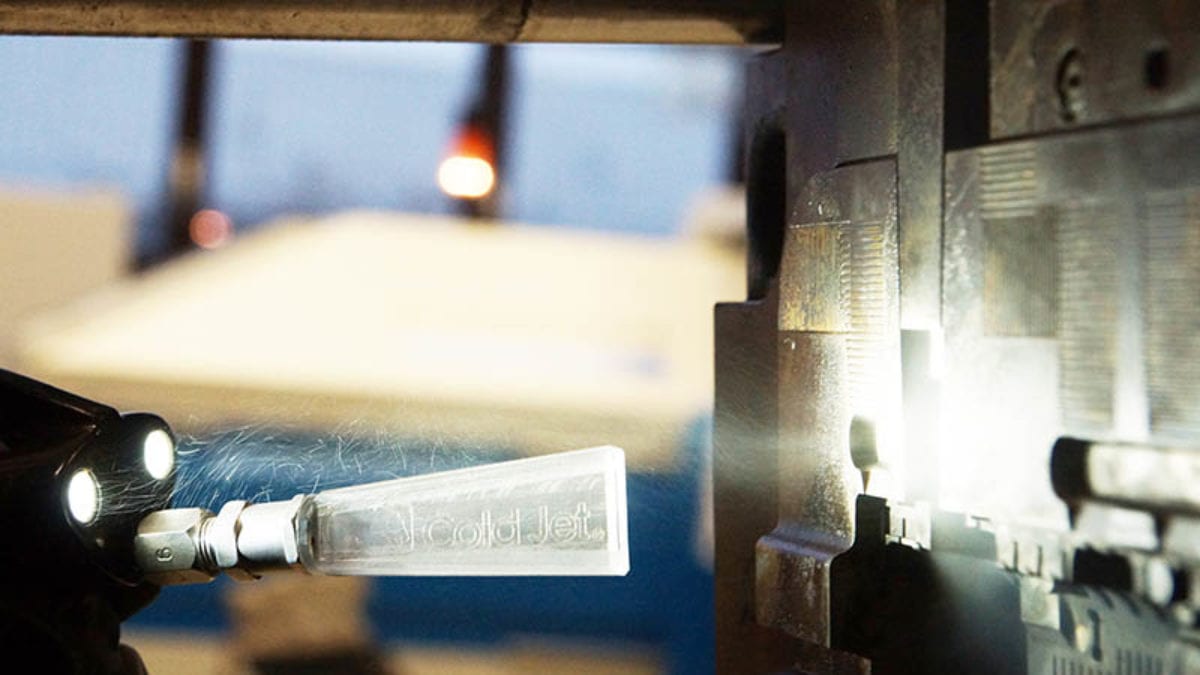

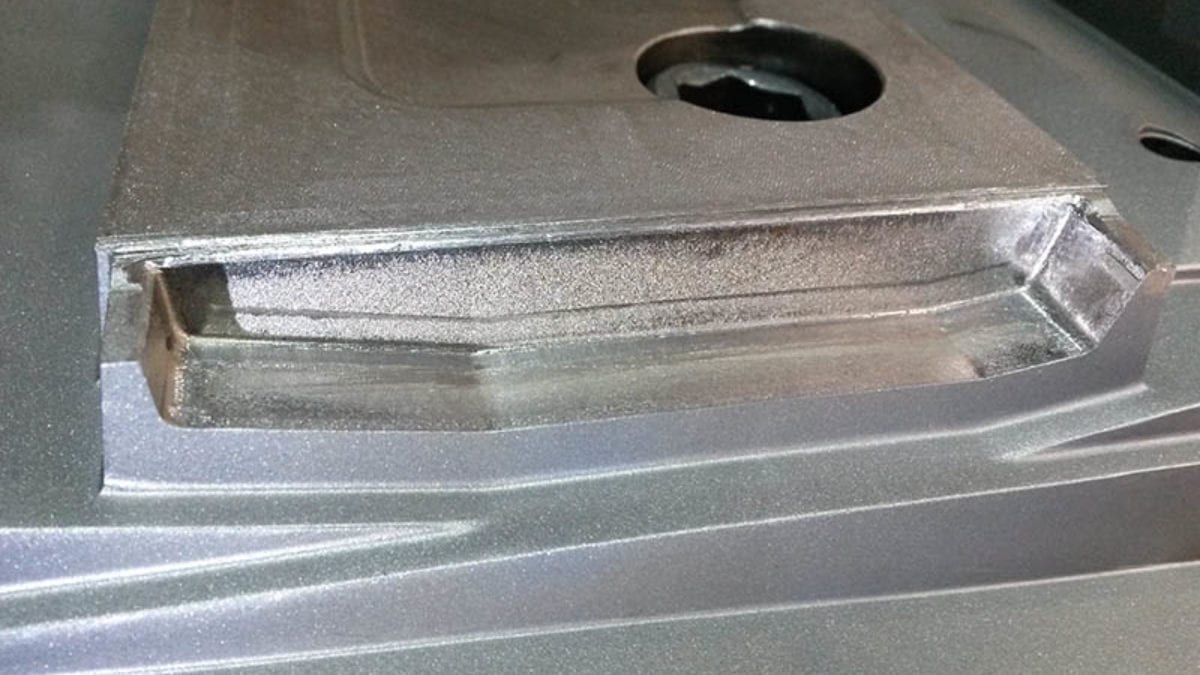

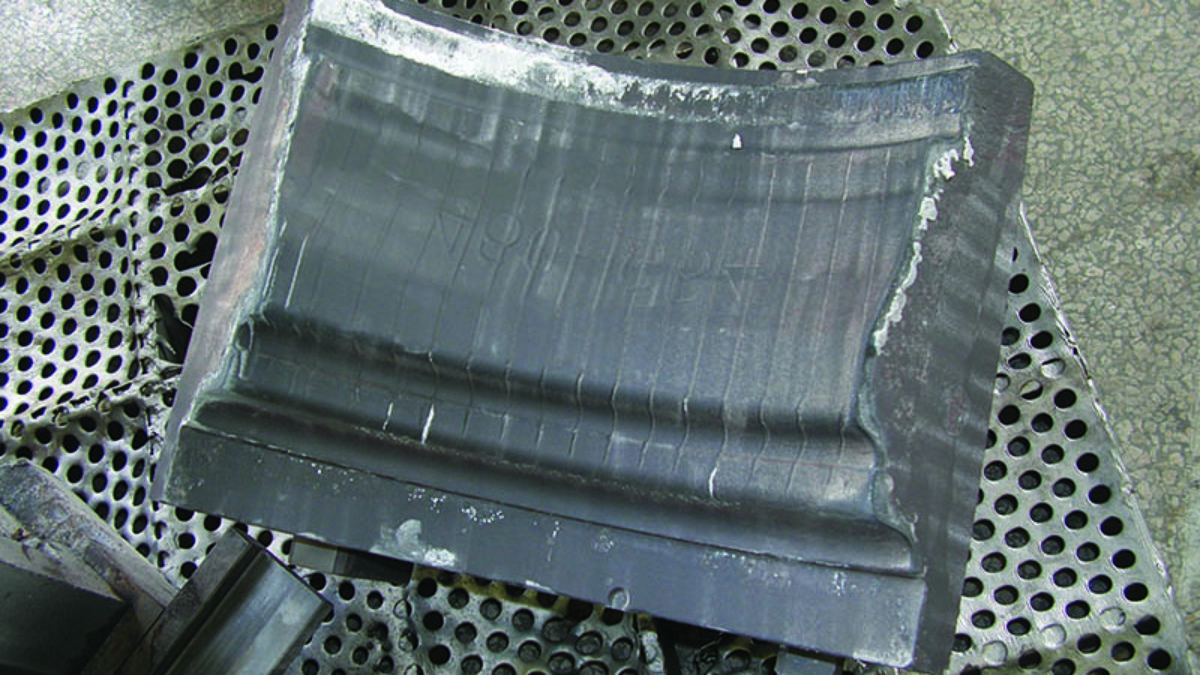

Mould Cleaning

Improve productivity by reducing downtime

BENEFITS

Dry ice blasting is a non-abrasive method that safely cleans moulds online, at operating temperatures.

- Improve product quality

- Clean in-place

Little to no disassembly required - Non-abrasive

No damage to moulds - Reduce scrap

Cleaner moulds lead to higher quality - Meet stringent industry demands

6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance) - Reduce production downtime

Clean quicker and without cooldown or disassembly - Decrease cleaning time and labour costs

- Eliminate painstaking manual cleaning

SPECIFIC USE CASES:

- Injection moulds

- Blow moulds

- Compression moulds

- Urethane moulds

- Textured moulds

- Slush moulds

- Technical moulds

- Extrusion dies

- Rotational moulds

- LSR and LIM moulds

- Thermoform moulds

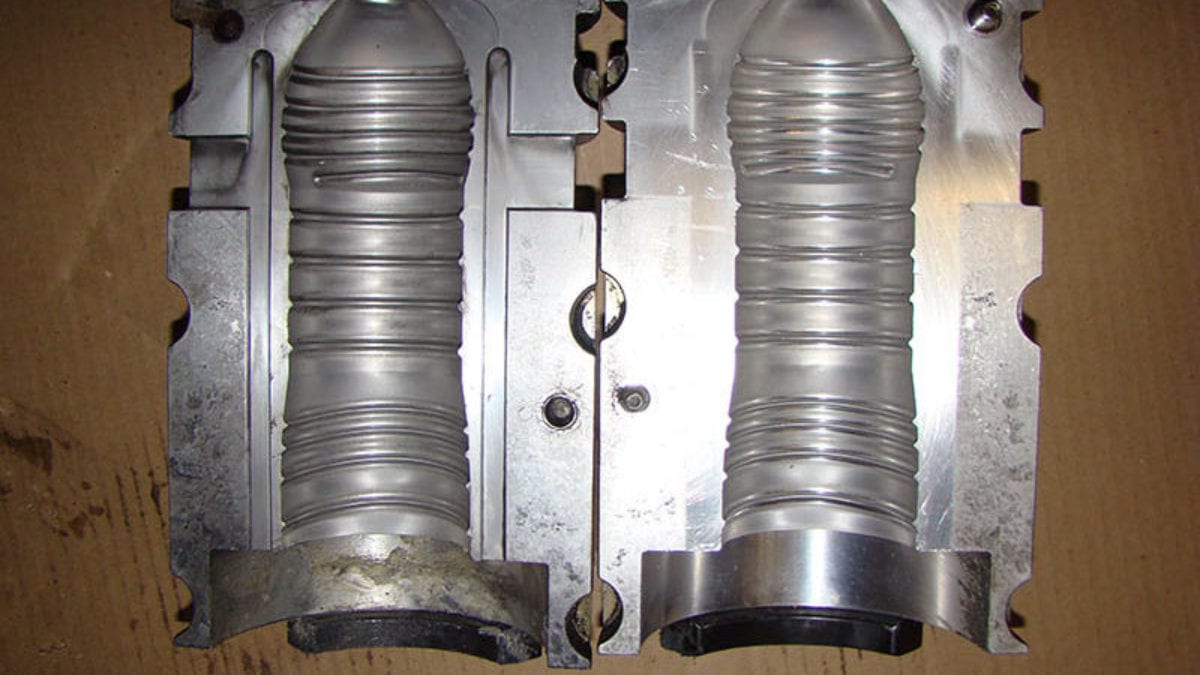

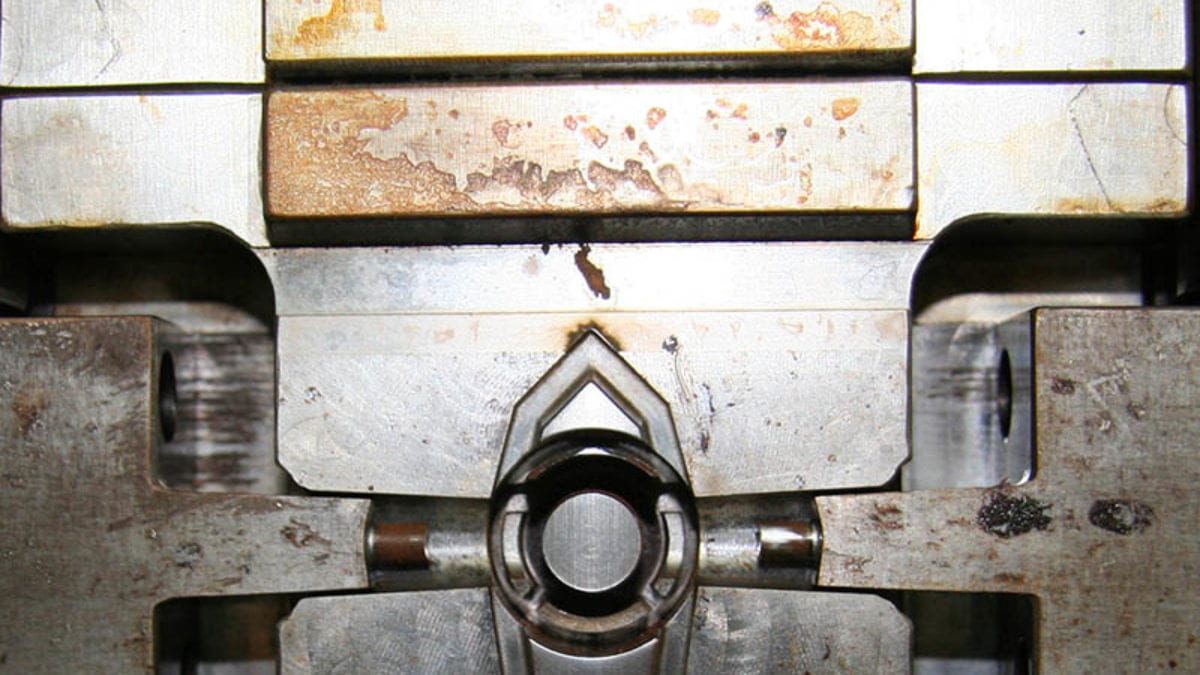

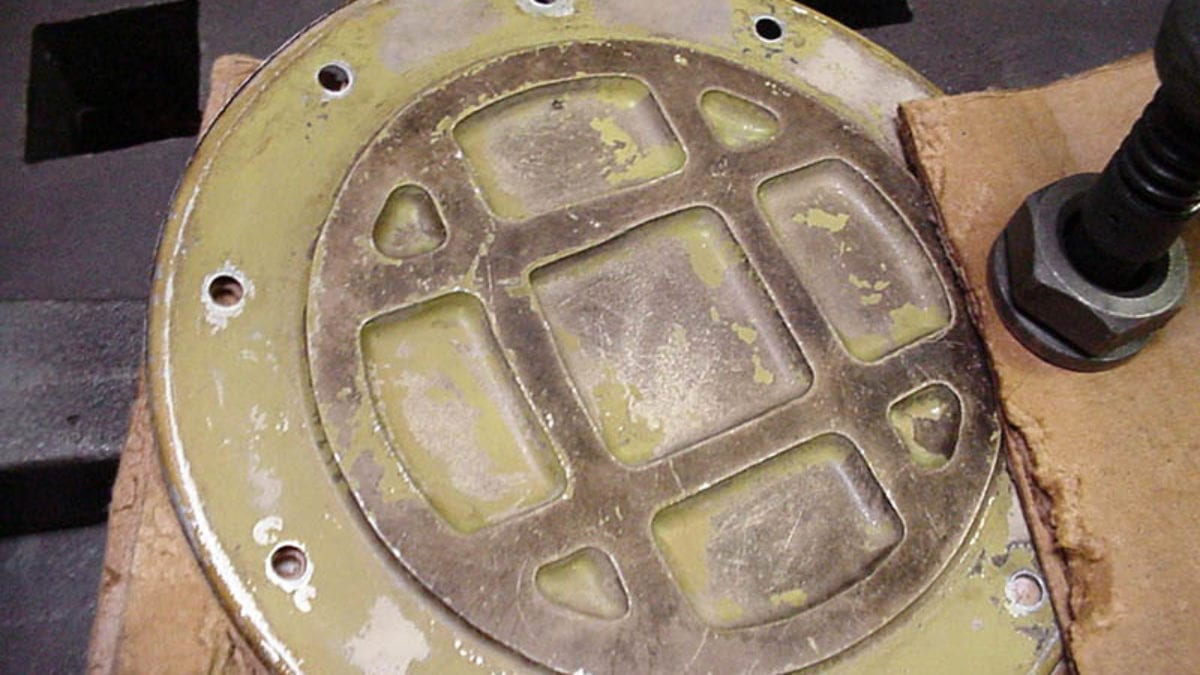

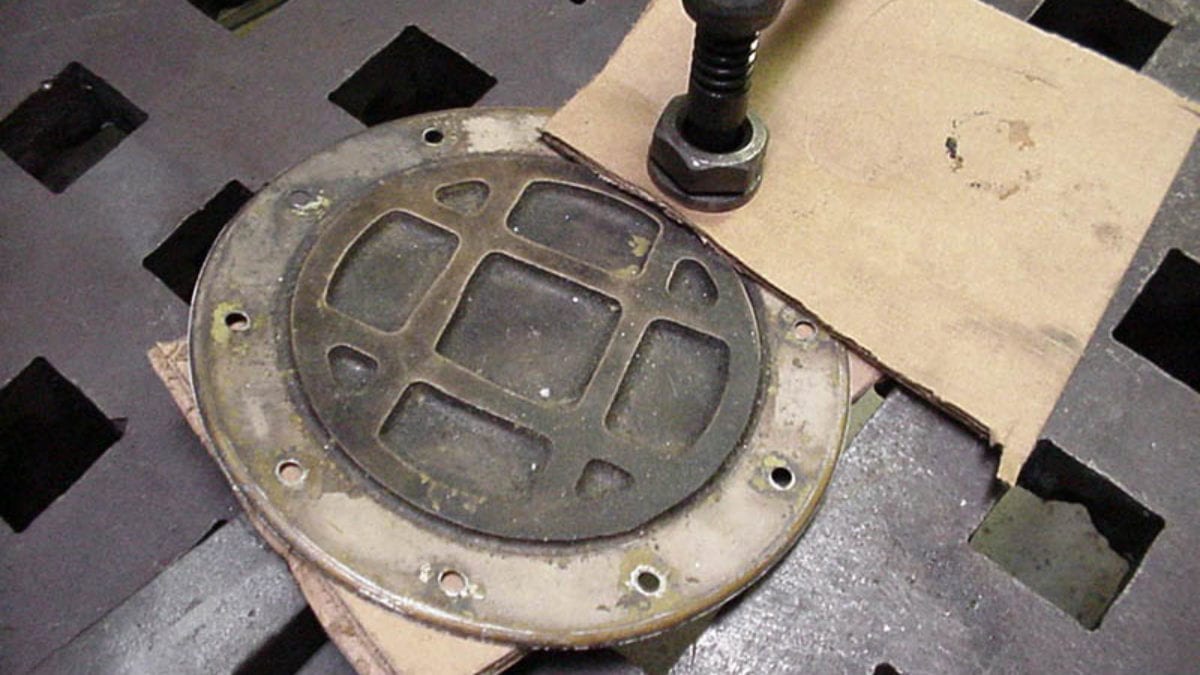

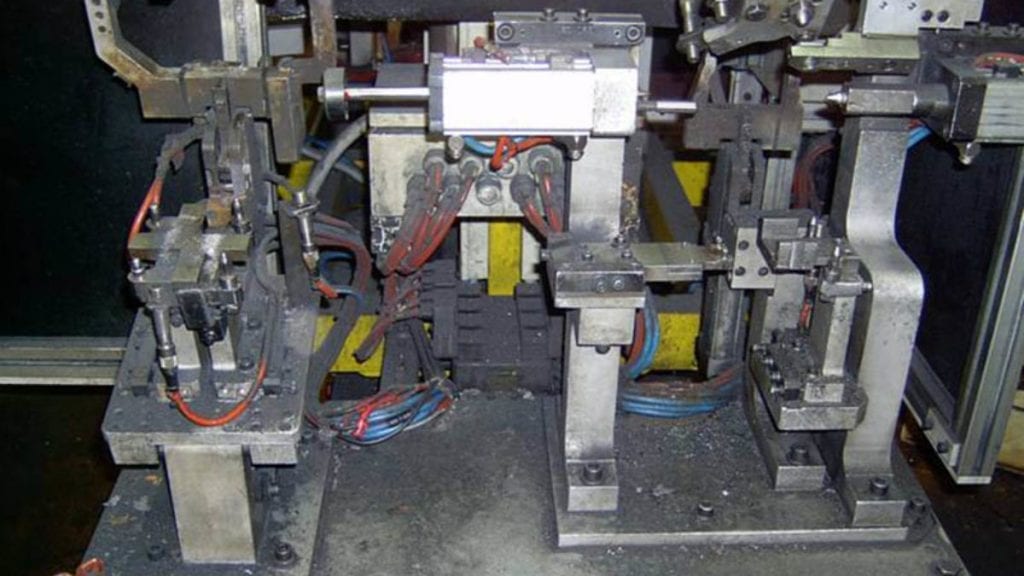

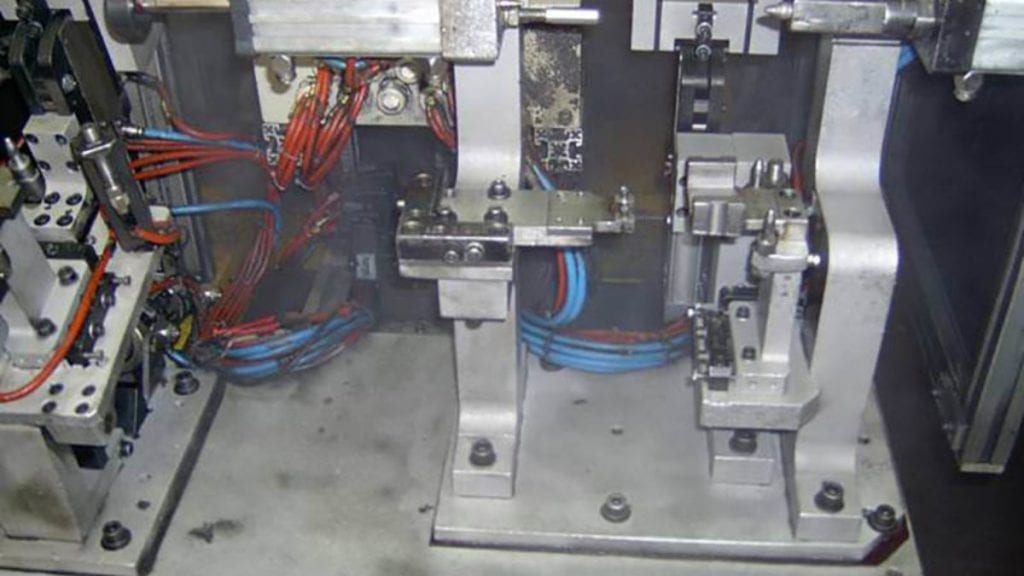

Core Box Preparation

Significantly reduce cleaning time without damaging vents

BENEFITS

Dry ice cleaning quickly and safely removes buildup of sand, resin and other residue without damaging core boxes.

- Reduce production downtime

- Safely clean without damaging vents or screens

- Eliminate disassembly

Clean while hot and in-place - Clean more effectively

- Eliminate waste disposal costs

- Environmentally responsible

- Deliver superior as-cast finish

SPECIFIC USE CASES:

- Cold boxes

- Half core boxes

- Dump core boxes

- Split core boxes

- Strickle core boxes

- Left and right hand core boxes

- Loose piece core boxes

- Gang core boxes

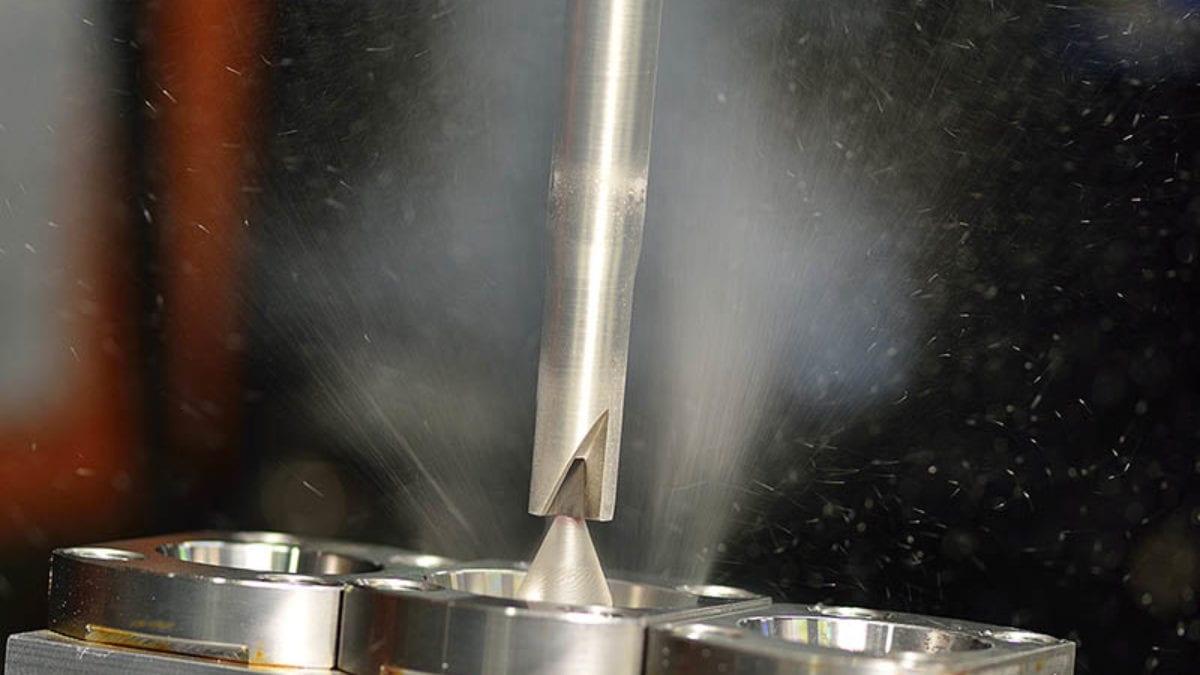

Die Cast Tooling Cleaning

Effectively clean forging dies while hot and online

BENEFITS

Dry ice blasting effectively removes scale, oxides and lubricants from die cavities without damaging equipment.

- Improve product quality

- Reduce production downtime

- Clean quicker and without cooldown or disassembly

- Non-abrasive

No damage to equipment - No secondary waste

- Eliminate painstaking manual cleaning

- Delivers superior as-cast finish

SPECIFIC USE CASES:

- Semi-solid casting tooling

- Squeeze casting tooling

- Low-pressure permanent moulding (LPPM)

- Permanent moulding

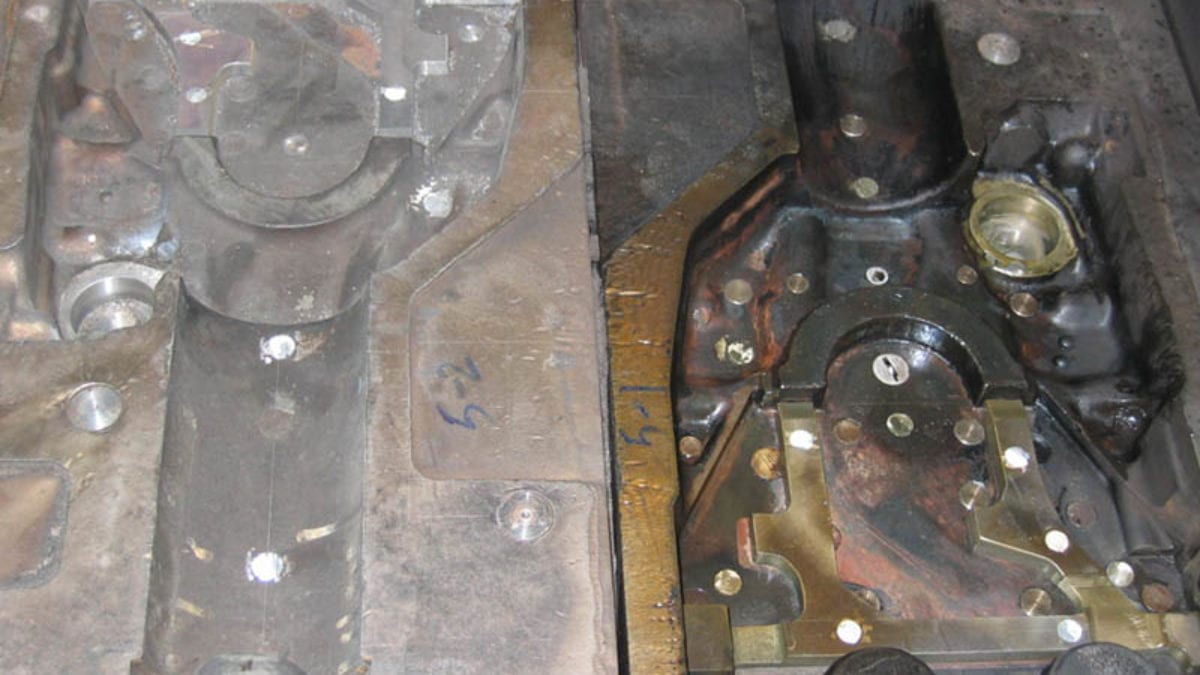

General Equipment Cleaning

Reduce cleaning time and production

downtime while prolonging life of equipment

BENEFITS

Dry ice cleaning quickly and effectively cleans production equipment without water, chemicals or secondary waste.

- Reduce cleaning time

- Eliminate manual cleaning with harmful chemical solvents

- Non-conductive cleaning process

- No secondary waste

- Non-abrasive

Eliminate wear and tear on machinery - Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

- Clean in-place

No disassembly required - Enhance Total Productive Maintenance (TPM) programs

SPECIFIC USE CASES:

- Fin cleaning and inspection

- Turbine engine nacelles

- Electronic components

- Compressor blades

- Brake assemblies

- Foam insulation

- Cargo bay areas

- Turbine engine components

- Tow hitches

- Landing gear systems

- Engine bay covers

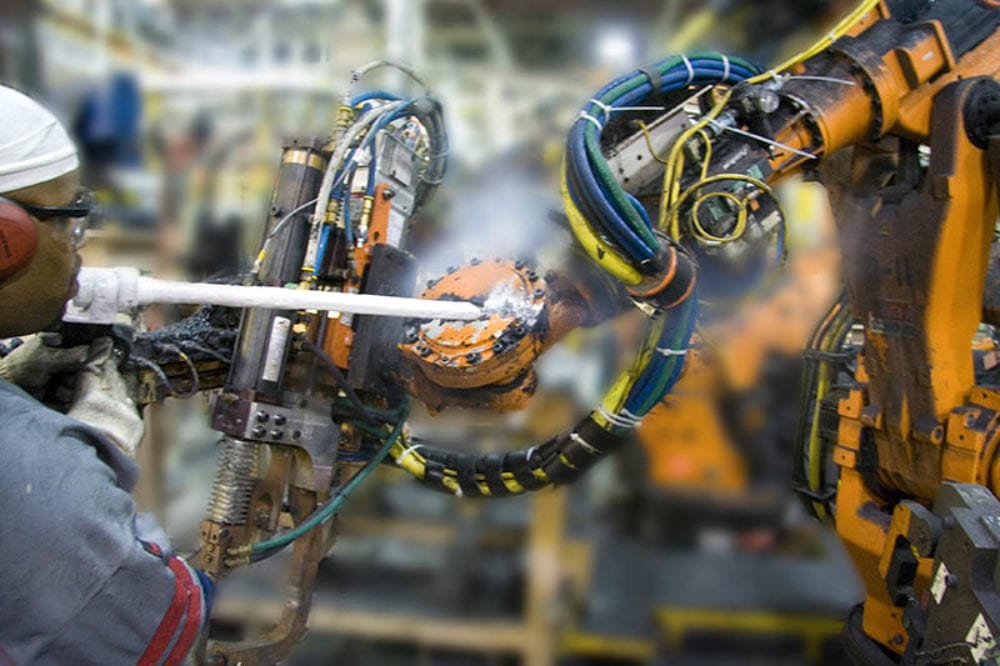

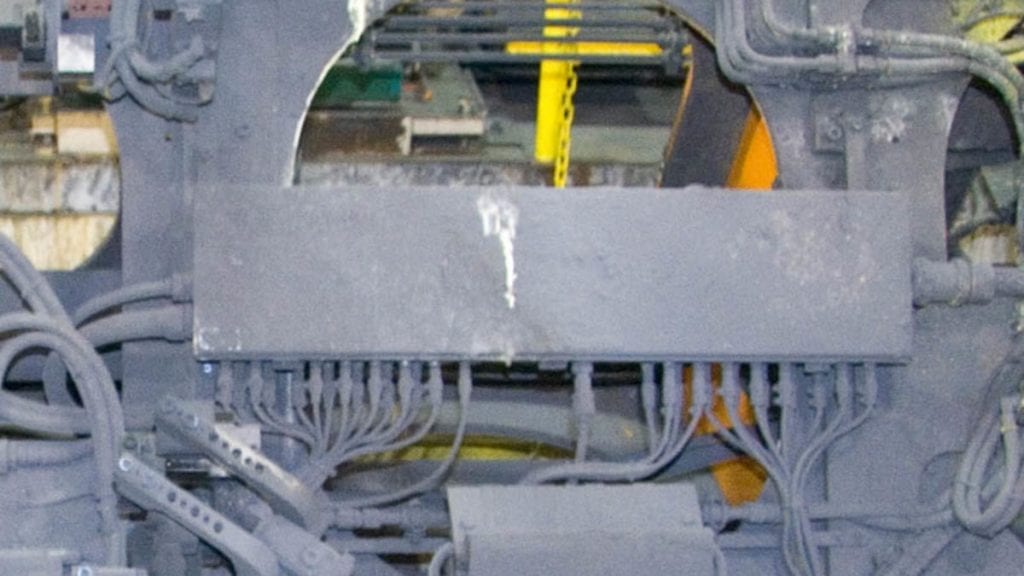

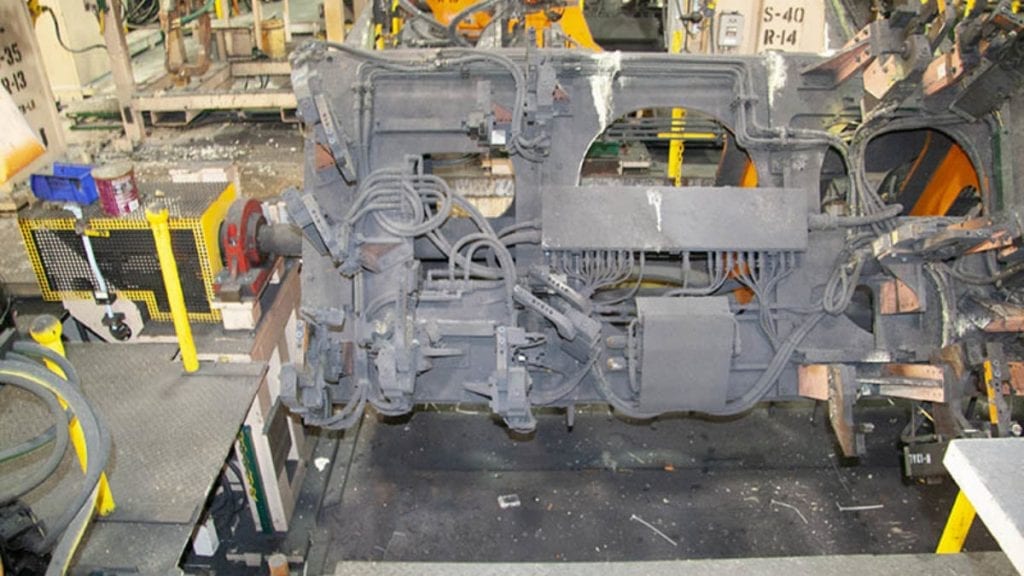

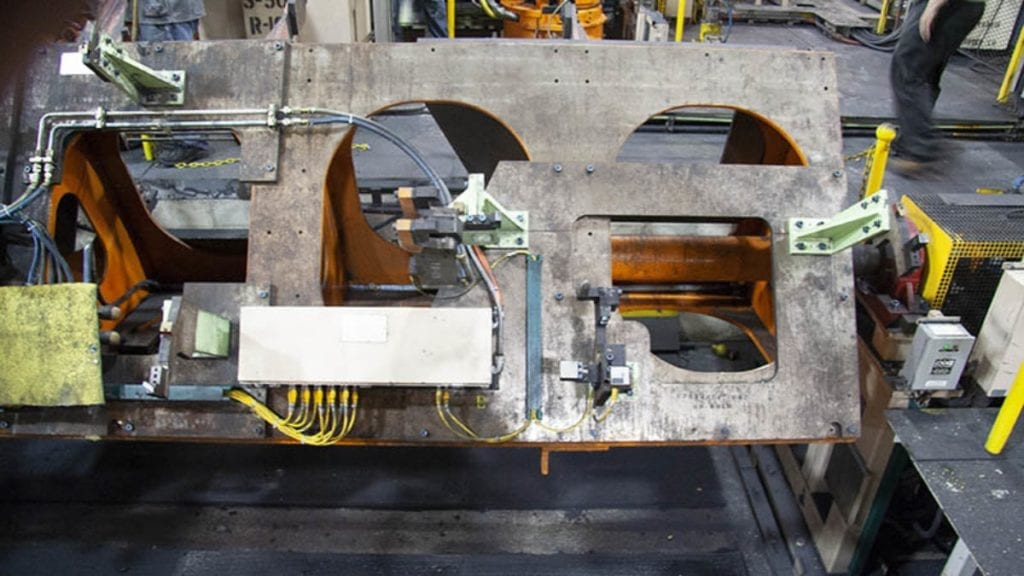

Weld Line Cleaning

Improve efficiency and accuracy of automated weld lines

BENEFITS

Dry ice cleaning eliminates misalignment, breakdowns and scrap by effectively removing weld slag and spatter buildup.

- Reduce scrap rates

- Maximise tooling life and decrease fixture repair

- Non-abrasive

Will not damage sensors - Replaces ineffective, costly and labor intensive cleaning methods

- Minimise downtime

- No secondary waste

- Environmentally responsible

- Clean online

No cool down required

SPECIFIC USE CASES:

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

- Proximity switches

BENEFITS OF DRY ICE BLASTING

Increase equipment productivity

and the quality of finished parts

Dry ice blasting effectively and safely cleans permanent moulding and die casting equipment without the need for disassembly.

→ Decrease cleaning time and labor costs

→ Non-abrasive

No damage to product or equipment

→ Clean in-place

No disassembly required

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream