POWER GENERATION

Reduce downtime and

unplanned outages

in power generation

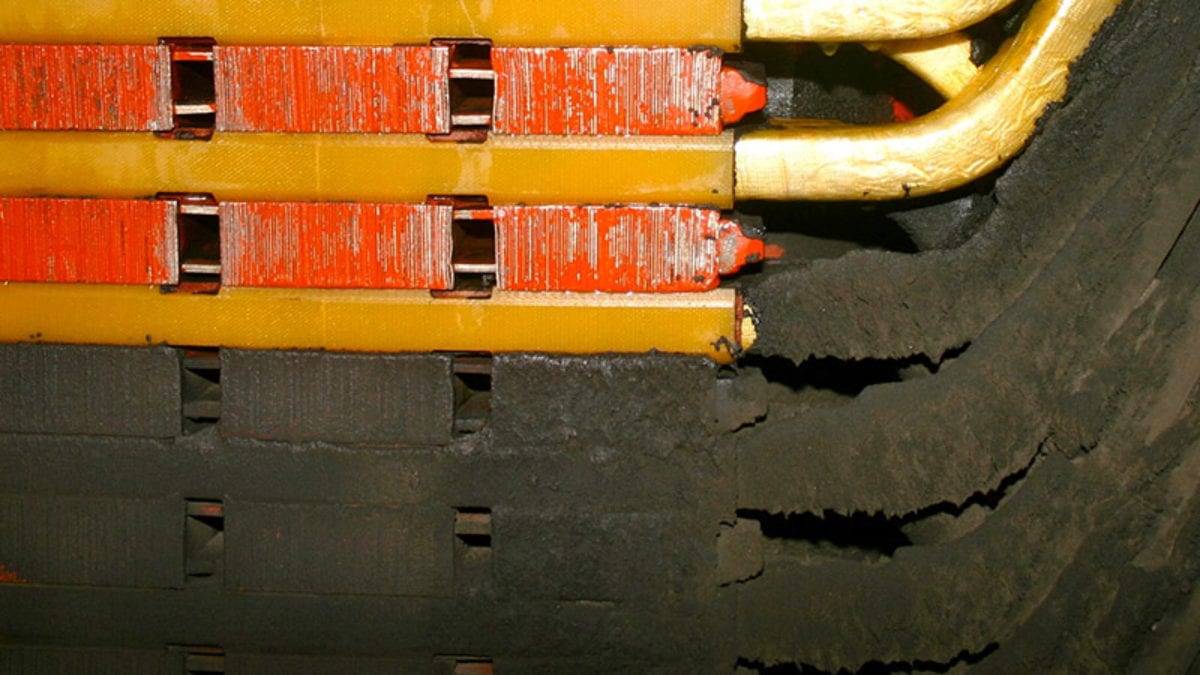

Dry ice blasting ensures regular maintenance of critical

path power equipment in power generation. The process

is non-conductive, non-abrasive and allows for effective

in-place cleaning without cooldown or disassembly.

CASE STUDIES

Revolutionise processes

to drive real results.

Natural Gas

Improve efficiency and reduce the risk of equipment failure

BENEFITS

Dry ice blasting enables the ability to clean in-place, which results in more frequent cleaning and improved equipment efficiency.

- Non-abrasive

No damage to delicate precision components - Dry cleaning process

No drying time - Clean in-place

Minimal to no disassembly - No flash rusting

- Reduce risk of unplanned production stoppages and costly repairs

- Better cleaning results

- Environmentally responsible

SPECIFIC USE CASES:

- Compressors

- Regenerators

- Combustion chambers

- Gas turbines

- Alternators

- Starting motors

- Heat recovery steam generators (HRSG)

- Heat exchangers

- Failed coating, corrosion, soluble salts and chloride removal

- Non-destructive testing

Hydroelectric

Clean generators more effectively,

resulting in more efficient operation

BENEFITS

Dry ice blasting helps maintain clean hydroelectric power equipment, which reduces risk of downtime and system failure.

- No secondary waste stream

- Limited containment setup

- Clean in-place

Minimal to no disassembly - Better cleaning results

- Access and clean tight spaces

- Improve operational efficiency

- Non-abrasive

No damage to delicate precision components - Environmentally responsible

SPECIFIC USE CASES:

- Water turbines

- Impulse and reaction turbines

- Coils

- Windings

- Stators

- Rotors

Nuclear

Safely and effectively clean nuclear power generation components

BENEFITS

Dry ice cleaning produces improved cleaning results, which leads to nuclear facilities operating at peak efficiency.

- Better cleaning results

- Dry cleaning process

No drying time - No secondary waste stream

- Improve operational efficiency

- Non-abrasive

- Clean in-place

- Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

SPECIFIC USE CASES:

- E-coat and powder coat lines

- Paint hooks

- Spray booths

- Paint shop rollers

- Guide rails

- Reduction gearboxes

- Perforated shielding

- Flooring

Steam Generation

Maintain high heat transfer efficiency

BENEFITS

Dry ice cleaning effectively cleans operating equipment and ensures steam generating systems are running at peak efficiency.

- Non-abrasive

No damage to delicate precision components - Dry cleaning process

No drying time - Clean in-place

Minimal to no disassembly - Reduce cleaning time and labour costs

- No secondary waste stream

- No flash rusting

- Reduce risk of unplanned production stoppages and costly repairs

- Better cleaning results

- Environmentally responsible

SPECIFIC USE CASES:

- Boilers

- Super heaters

- Economisers

- Heat recovery steam generators (HRSG)

- Air preheaters

- Steam turbines

- Alternators

- Condensers

- Heat Exchangers

- Non-destructive testing

- Failed coating, corrosion, soluble salts and chloride removal

Substations

Regularly maintain equipment to

ensure highly efficient operation

BENEFITS

Dry ice cleaning quickly cleans substation equipment, which reduces operational downtime and the risk of system failure.

- Faster cleaning process

- Dry cleaning process

No drying time - Non-abrasive

No damage to delicate precision components - No secondary waste stream

- Corrosion removal

- Improve operational efficiency

- Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

SPECIFIC USE CASES:

- Insulators

- Arresters

- Transformers

- Circuit breakers

- Isolators

- Bushings

- Switchgears

- Motors

- Gas turbines

BENEFITS OF DRY ICE BLASTING

Maintain peak operational efficiency

Dry ice blasting safely and effectively cleans a wide range of power generation equipment, leading to optimal efficiency.

→ Reduce unplanned downtime and risk of catastrophic failure

→ Clean online

Clean faster and with little to no disassembly

→ Non-abrasive

No damage to delicate precision components

→ Non-conductive

→ Increase polarization indices

→ Improve megohm readings

→ Improve thermal dissipation

→ Environmentally responsible and employee safe