MINING

Keep mining fleet and operations

equipment running at peak

efficiency and prolong asset life

Revolutionise processes

to drive real results.

Dry ice blasting saves both time and money in the mining industry.

Dry ice blasting provides a non-conductive, environmentally responsible cleaning process that does not create secondary waste.

It safely removes contaminants from production machines, maintains high efficiency of assets, improves inspection processes and decreases downtime, all while prolonging the life of equipment.

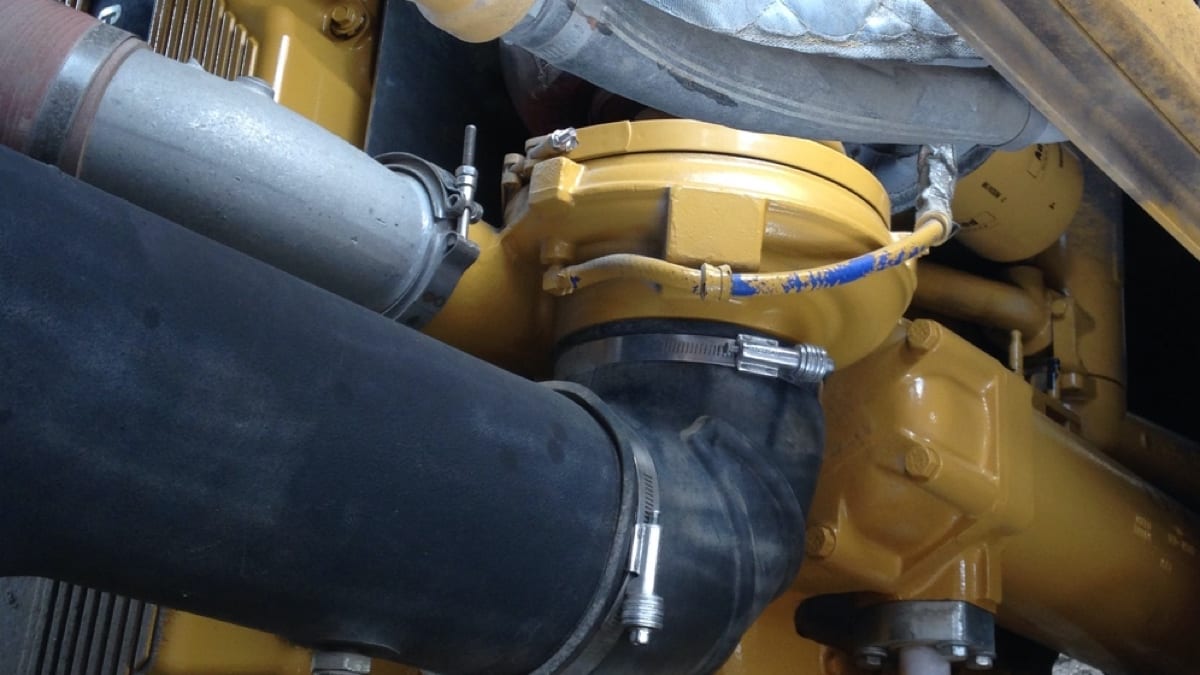

Operational Equipment Cleaning

Ensure high equipment efficiency with non-abrasive cleaning

BENEFITS

Dry ice blasting effectively removes buildup from mining production equipment, enabling it to operate more efficiently, while reducing the risk of breakdowns.

- Reduce production downtime and unplanned maintenance

- Faster and more effective cleaning

- Non-abrasive

Eliminate wear and tear on machinery - Improve inspection processes

- Non-conductive

- Improve preventative maintenance and 5S

- No secondary waste stream

- Environmentally responsible

SPECIFIC USE CASES:

- Extraction equipment

- Dyna veins

- Ring gears

- Compressors

- Bleeders

- Pumps

- Hydra slides

- Lube rooms

- Bitumen and carbon buildup removal

- Equipment degreasing

- Transport vehicles – Trucks and railcars

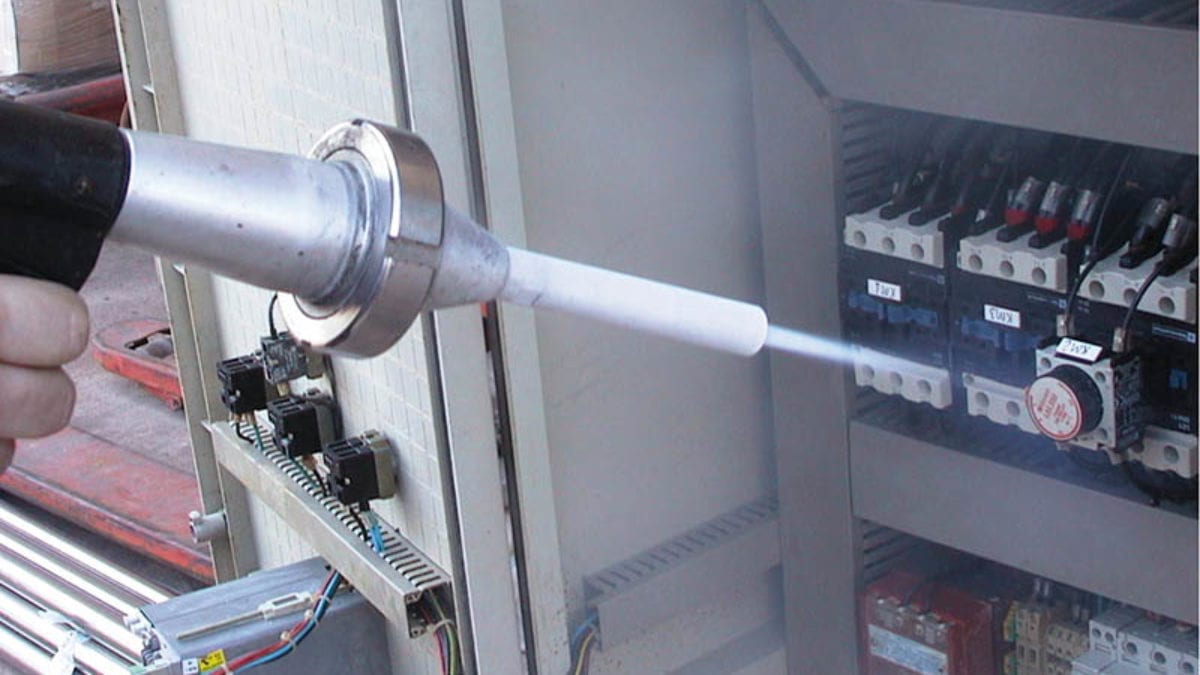

Electrical Component Cleaning

Safely clean electrical equipment

and reduce maintenance costs

BENEFITS

Dry ice blasting safely cleans buildup from sensitive electrical equipment and reduces the risk of unplanned production downtime.

- Increase production time

- Maintain high equipment efficiency

- Quickly and effectively clean components

- Non-abrasive

Will not damage sensitive electronics - Improve inspection processes

- Non-conductive

- Improve preventative maintenance

- No water or secondary waste streams

SPECIFIC USE CASES:

- Electric motors

- Stator windings

- Electrical rooms

- Switchgears

- PCR rooms

- Fans, screens and housings

- Insulators

- Generators

- Electric boxes

- Bitumen and carbon buildup removal

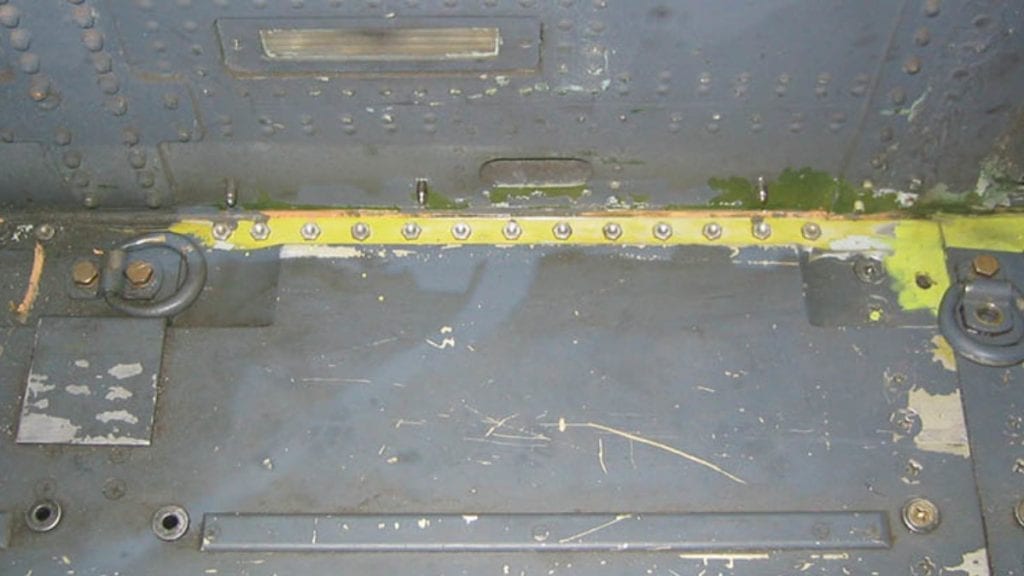

Surface Preparation

Prepare surfaces with a dry process that allows

for immediate coatings/paint application

BENEFITS

Dry ice cleaning is a dry process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate paint or coating after cleaning

- No secondary waste

Reduce disposal costs - Non-abrasive

Will not damage parts - Improve product quality

- Environmentally responsible

SPECIFIC USE CASES:

- Interior parts

- Exterior parts

- Cleaning surfaces before RTVs

BENEFITS OF DRY ICE BLASTING

Effectively clean heavy buildup

from production machinery

and electrical equipment

Clean equipment is able to operate at peak efficiency, which reduces the risk of unplanned downtime and prolongs equipment life.

→ Reduce production downtime and unplanned maintenance

→ Clean faster and more effectively

→ Non-abrasive

Will not damage equipment

→ Improves preventative maintenance and 5S

→ Environmentally responsible

→ No secondary waste stream

→ Non-conductive

→ Clean in-place

No disassembly required

→ Versatile clean