DRY ICE BLASTING APPLICATIONS:

Airline Catering

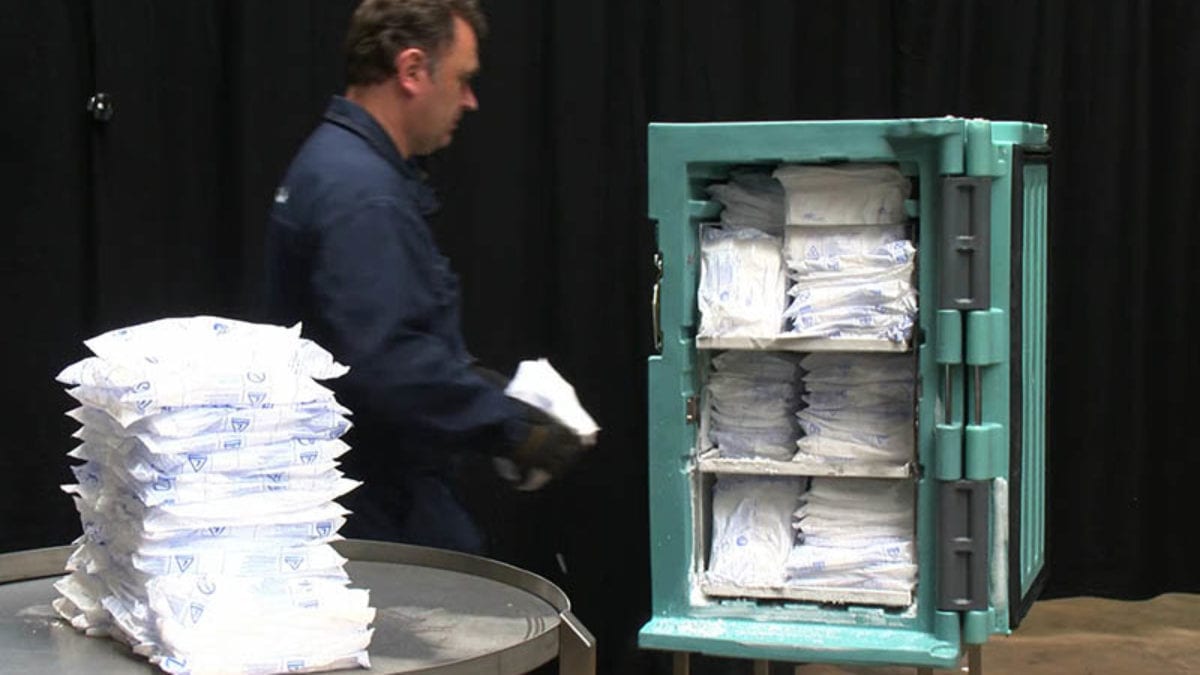

Cold Jet are pleased to provide exceptional dry ice services for airline catering applications. Airline caterers use large quantities of dry ice on a daily basis and dry ice represents a large percentage of non-food consumable costs. The Cold Jet solution is to provide airlines with leading dry ice manufacturing technology, to successfully produce and rely on high-quality dry ice for the storage, refrigeration and packaging of airline catering.

Within the airline catering industry, complex scheduling often leads to dry ice waste and inefficiency. By producing your own dry ice, airline caterers have complete control over dry ice availability, quality and cost. Airline caterers experience decreased costs and greater flexibility with onsite dry ice production – it’s time to reduce waste and inefficiency; rely on leading Cold Jet production technology.

Speak to a Dry Ice Machine Expert Today

Onsite dry ice production is the ideal solution for onboard cooling in the airline catering industry

High-quality dry ice blocks can aid the airline catering industry to ensure prepared meals are kept fresh when transported from the catering kitchen to the aeroplane. Dry ice leaves no residue behind, is extremely sanitary, and will keep prepared catering packages fresh for long durations. By investing in a Cold Jet production machine, airline caterers can save labour, time, money and effort. Dry ice production equipment also allows airline catering companies to be flexible with dry ice on short notice.

Airline Catering Dry Ice Manufacturing

Cold Jet are the leading providers of exceptional dry ice production equipment and machinery. We provide a range of dry ice production machines available to a variety of industries, including airline catering.

Airline caterers experience decreased costs and greater flexibility with onsite dry ice production. Producing dry ice onsite leads airline caterers to reduce waste and decrease costs, while enabling them to meet unexpected changes to demand. Using our equipment, our loyal customers have access to Cold Jet CONNECT™, where we can remotely monitor, diagnose and implement corrective actions on dry ice manufacturing equipment.

BENEFITS OF DRY ICE EQUIPMENT FOR AIRLINE CATERING

Greater flexibility to meet demands

Eliminate risk of over or under ordering

EPA, FDA & USDA approved for use around food

Eliminate dry ice waste

No residue or water left behind

Fully automated, easy to use machines

Eliminate cooling (3x the refrigeration power of water ice)

Eliminate delivery & storage costs

Cut costs & improve operational efficiency

The widest selection of dry ice production machines

Find the right machine for your production needs.

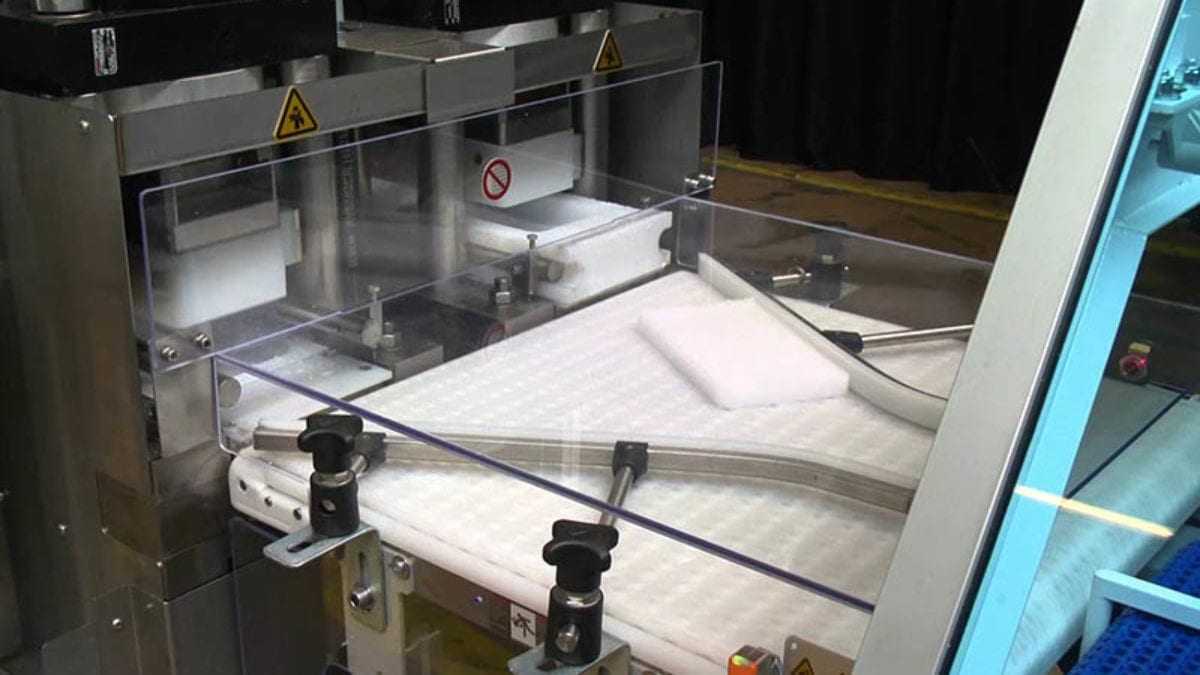

High-Efficiency Line

Producing fresh, high-quality dry ice on demand

Produce up to 265 lbs (120kg) per hour

PR120H

Produce up to 772 lbs (350kg) per hour

PR350H

Produce up to 1,653 lbs (750 kg) per hour

PR750H

Frequently Asked Questions About Dry Ice for Airline Catering

What Are the Advantages of Using Dry Ice?

Dry Ice Production Saves Time

On top of airline catering, dry ice production can be used in a wide range of applications and is incredibly time-saving and efficient when compared to alternative methods. As an organisation that relies on regular dry ice production and manufacturing for operations, having your own technology will be incredibly cost-effective.

Dry Ice is Safe

Dry ice manufacturing, production and blasting for cleaning is safe, as it relies on carbon dioxide. The process of dry ice blasting is non-toxic and non-flammable. In fact, dry ice is so safe that the use has been approved for commercial use around food by the EPA, FDA and USDA.

Dry Ice Is Sustainable

Using our technology and dry ice machines is much more sustainable than other alternative methods. Our equipment utilises materials that are inert, non-conductive and non-corrosive. There is no secondary toxic waste, moisture, or residue leftover when producing or using the produced dry ice. As such, our methods do not produce any harmful chemicals or hazardous waste. When relying on dry ice for airline catering, the produced dry ice is produced from reclaimed CO2 and does not add any additional CO2 into the atmosphere.

Why Choose Cold Jet for Airline Catering Dry Ice?

Cold Jet is the global leader in dry ice production technology, providing innovative solutions that save companies time, money and resources. We offer the most advanced dry ice manufacturing systems with superior end-product quality, coupled with 24/7 production capability and customer support. Quality dry ice starts with your equipment. As one of the leaders in dry ice manufacturing, production and equipment, Cold Jet offer the most advanced manufacturing systems with superior end-product quality.

Our dry ice production equipment and dry ice machinery are among the most innovative and reliable technology available in the country. With a focus on high-quality, we’re certainly not the cheapest dry ice equipment supplier; nor should you want us to be. Our core deliverables are centred on maintaining exceptional, consistent and innovative dry ice machinery design, so you can continue producing great-quality dry ice.

What Else Can Dry Ice Be Used For?

Dry ice comes with many different uses and applications. If you’re looking at buying a dry ice machine for airline catering, you may require such equipment to satisfy a demand for ongoing dry ice requirements. Generally speaking, those in the airline catering, medical, research, pharmaceutical, food and shipping industry require dry ice production equipment for refrigeration, storage, cooling and climate control.

Dry Ice Blasting is the method of using carbon dioxide in a pressurised air stream for surfaces or objects. The technique of dry ice blasting is extremely effective for a number of cleaning and surface preparation applications. The main uses for dry ice are:

- Adhesive Removal

- Coating & Corrosion Removal

- Composite Tool Cleaning

- Core Box Cleaning

- Equipment Cleaning

- Historical Restoration

- Mould Removal

- Part Finishing

- Remediation

- Surface Preparation

- Weld Line Cleaning

- Dry Ice Manufacturing for Airline Catering

- Dry Ice Cooling in Food Processing

- Cooling for medical resources

- Camping

- Shipping refrigeration

- Recreational use (parties, restaurants, events)

What Industries Do Cold Jet Work With?

Cold Jet service and engage with a broad scope of industries across Australia. Our diverse client portfolio means that we can provide dry ice solutions to meet a wide variety of applications, including airline catering. The primary industries that we service include:

- Aerospace and Aviation

- Automotive

- Contract Cleaning

- Engineered Wood

- Food and Beverage

- Foundry

- Medical Device

- Mining

- Oil and Gas

- Packaging

- Plastics and Composites

- Power Generation

- Printing

- Public Transportation

- Restoration and Remediation

- Rubber and Tires

- Textiles

Is Dry Ice Safe?

Yes, dry ice production is safe, non-toxic and non-flammable. Dry ice is so safe that it is EPA, FDA, and USDA approved for commercial use around food.

Looking to Purchase Dry Ice Equipment?

The most reliable and durable dry ice machines for production can be found at Cold Jet. Our dry ice production equipment features unparalleled technology and can be used in a variety of industries. Choose from a range of:

- Brand New Machines

- Certified Pre-Owned Equipment

- Certified Demo Equipment

Repeat customer? That’s perfect! We have a customer loyalty trade-in program, which allows the buyer to receive up to $10,000 towards the purchase of another machine.

Can I Buy Dry Ice From Cold Jet?

Yes! You can find the highest quality dry ice for sale at Cold Jet. We compress dry ice into dry ice pellets here in Australia, shipping dry ice across the country. We can also create dry ice blocks or slabs, depending on your requirements. We’re known for supplying dry ice at the highest density in Australia, with the highest quality storage boxes to match.

Get Started with Dry Ice Today

We beat other dry ice suppliers because we have a capable team that not only manufacture dry ice, but we offer cleaning services as well. Between our dry ice manufacturing line, our blasting equipment, our rental of such equipment and our fast and reliable delivery of dry ice across Australia, we’re here to provide the best solution for your requirements, including airline catering. Get in touch with our friendly team to find out more about dry ice airline catering solutions – we’re available on 1300 COLDJET.