DRY ICE CLEANING PRINT INDUSTRY

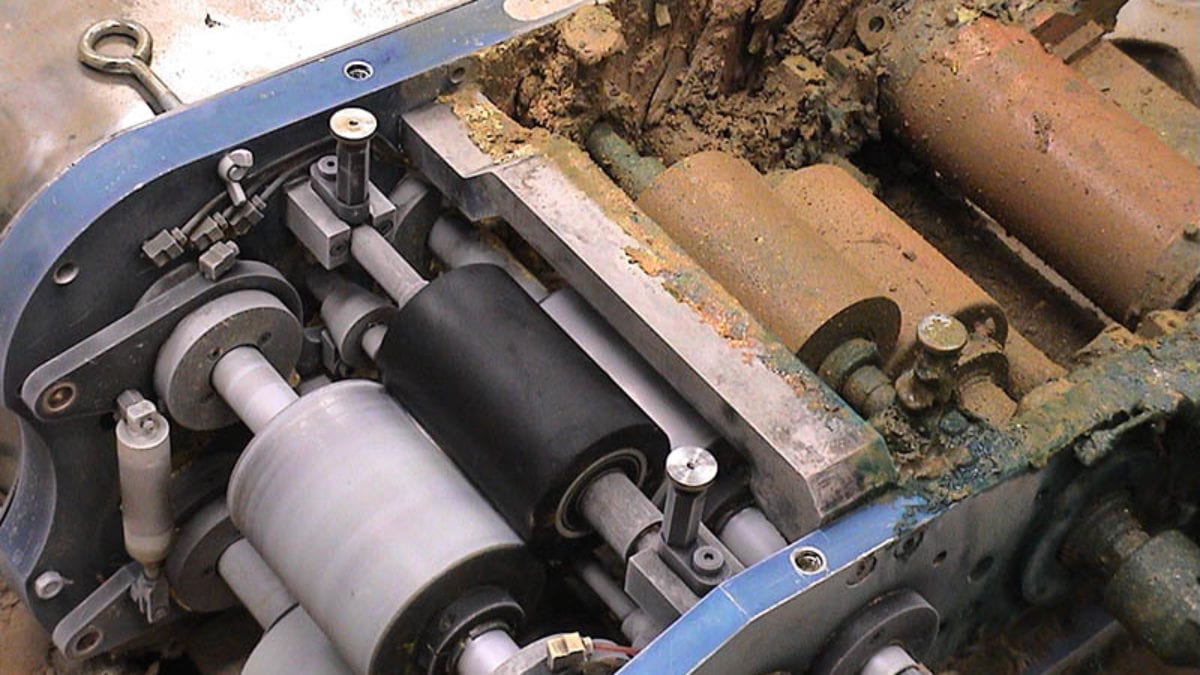

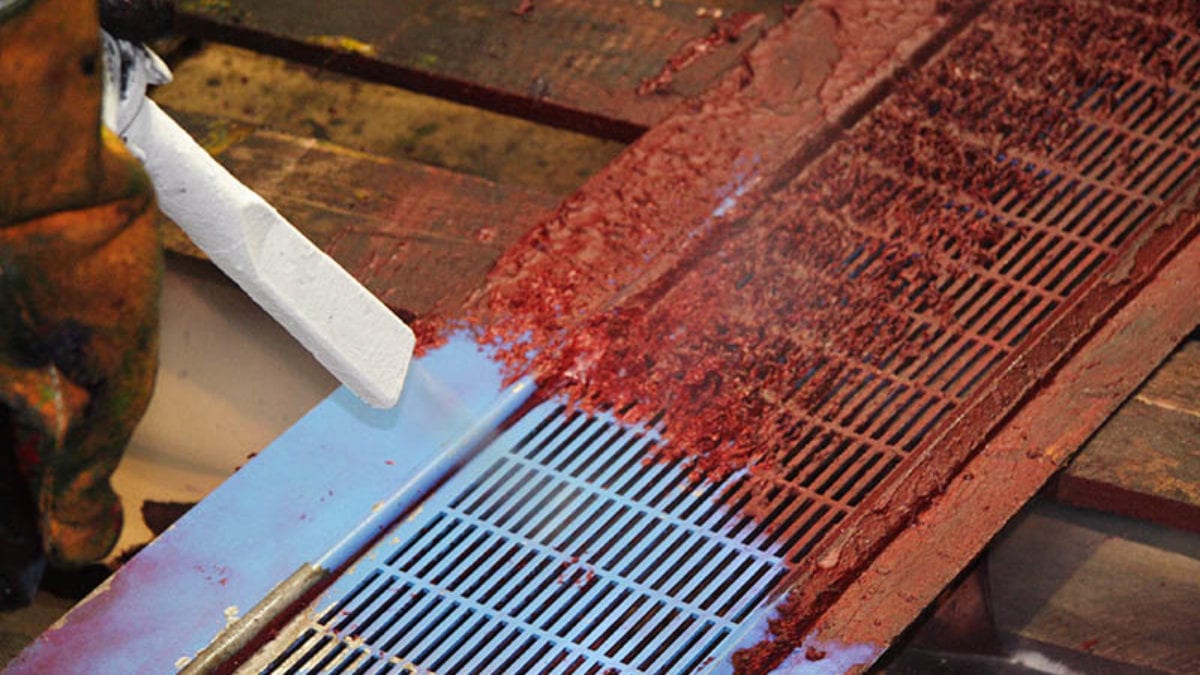

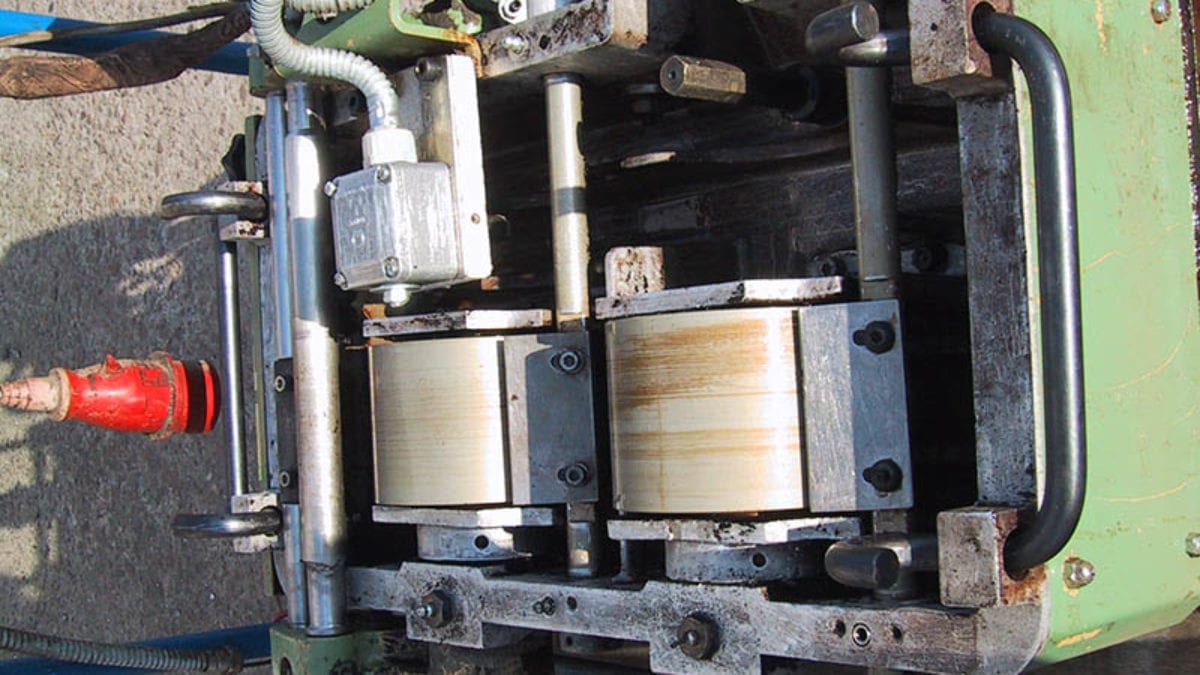

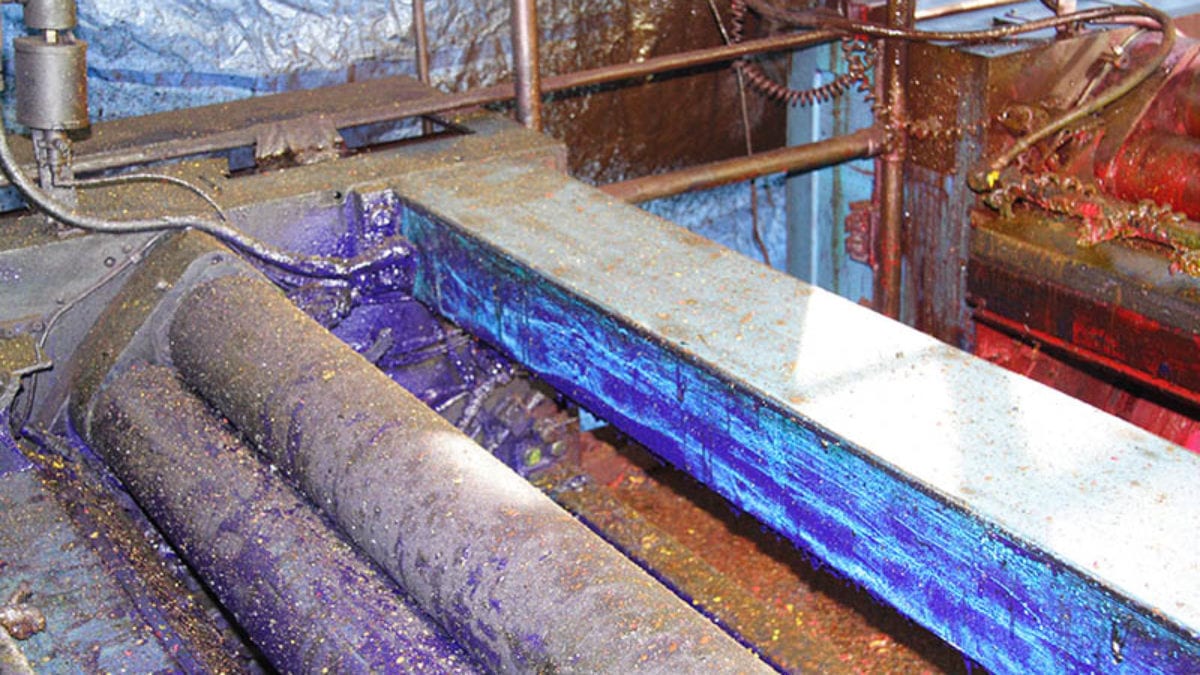

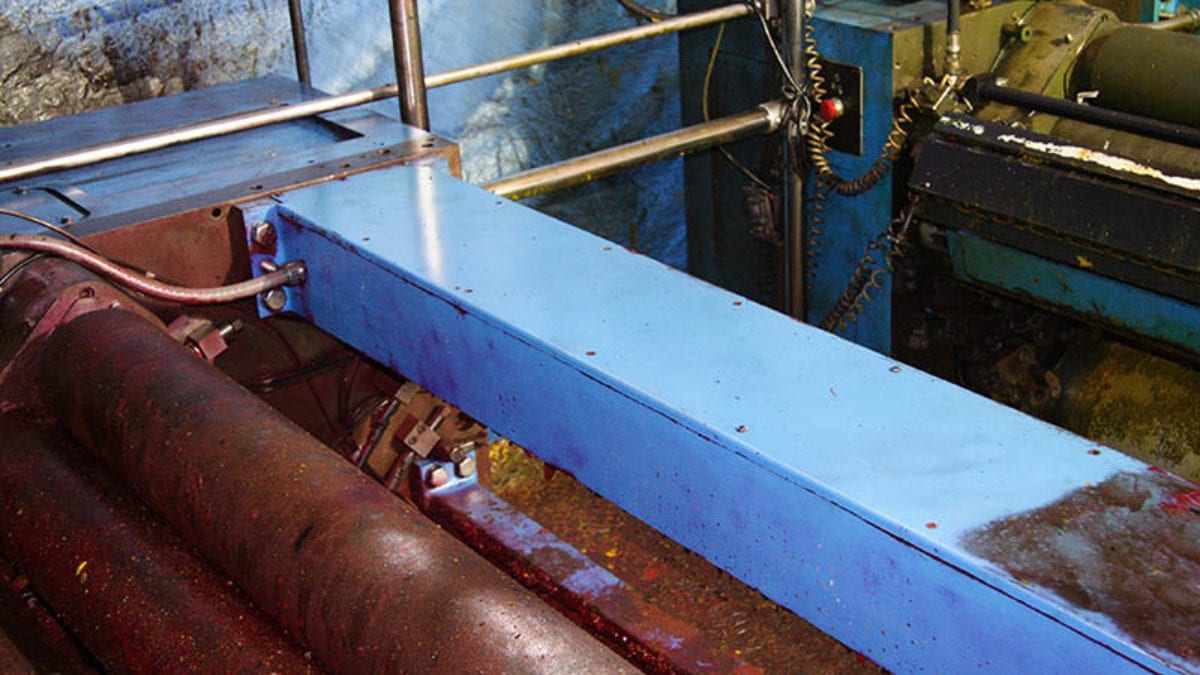

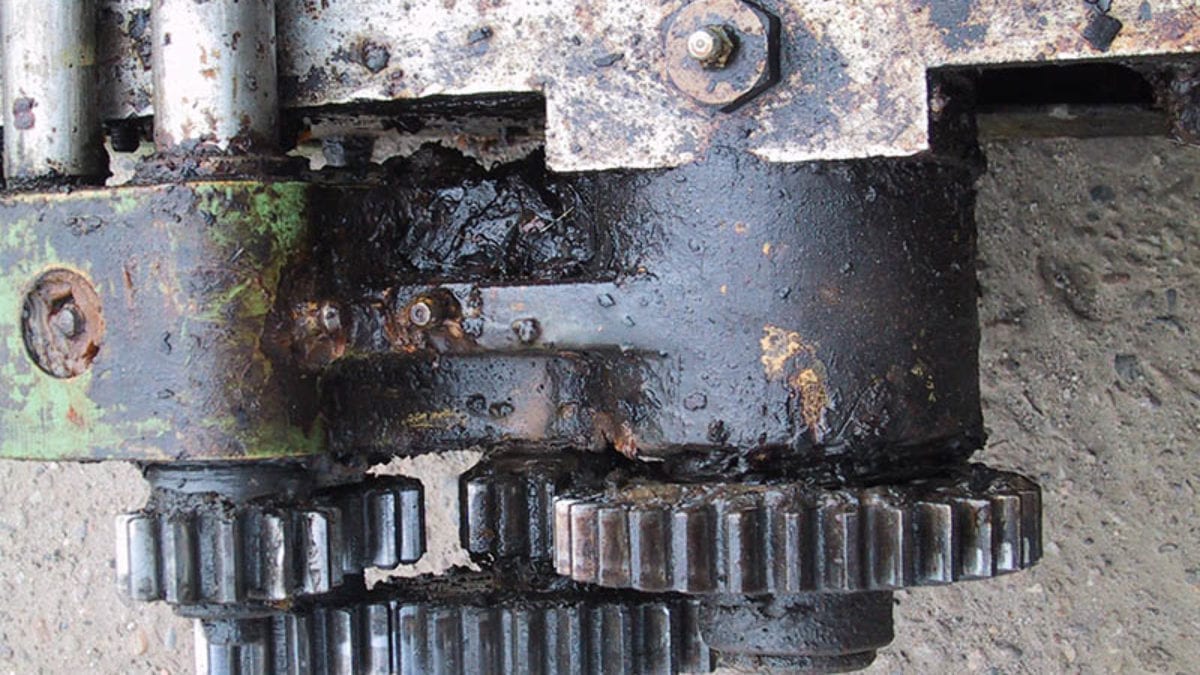

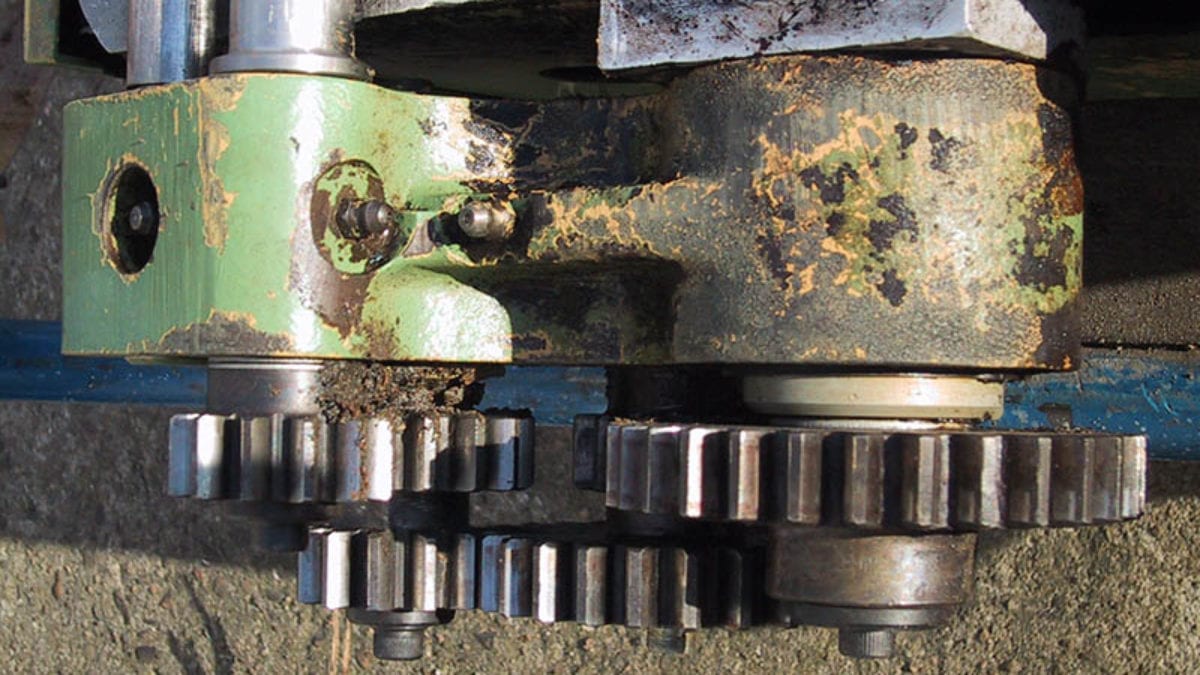

Cold Jet have years of experience providing the best dry ice cleaning print industry applications available. Dry ice blasting quickly cleans printing machinery parts with little to no disassembly or downtime. The process easily and accurately cleans burnished ink, heavy grease and caked-on paper dust without chemicals or damage to sensitive and expensive components. Clean your printing equipment more efficiently, effectively and easily with Cold Jet’s leading dry ice cleaning print industry solutions.

Dry ice blasting, also known as dry ice cleaning, is a method that uses carbon dioxide in a pressurised air stream for surfaces or objects. Our dry Ice blasting services provide a highly efficient and environmentally friendly solution for printing equipment. Operating in the print industry, you’re likely aware of how damaging contaminants, dirt, grime and operational build-up can be to performance. The best way to avoid problems with your printing machinery, is to rely on an efficient, powerful and safe cleaning method like dry ice cleaning.

Printing Equipment Cleaning

Clean more efficiently, reduce downtime & eliminate scrap

BENEFITS

Dry ice blasting quickly and easily removes buildup from printing machinery components.

- Non-abrasive

- Will not damage equipment

- Reduce scrap rates

- No secondary waste

- Reduce cleaning time and resulting downtime

- Reduce labour costs

- Clean online

- Eliminate manual cleaning

- Environmentally responsible

- Employee safe

SPECIFIC USES:

- Drums

- Feeder units

- Delivery units

- Flexography

- Gear and deck guides

- Grippers

- Rollers

- Gravure presses

- Ink trays

- Letterpresses

- Side walls

- Vent slots

- Electronic components

Speak to a Dry Ice Print Expert Today

Dry Ice Cleaning Print Equipment

Cold Jet provide leading dry ice cleaning solutions for printing equipment. The nature of dry ice means that our cleaning solutions are strong and powerful, removing all tough contaminants; and yet, gentle enough to protect equipment parts and not damage any surfaces. Dry Ice cleaning printing solutions are our specialty at Cold Jet – we have cleaned hundreds of printing presses and built a steady client base of those working in the printing industry.

When you rely on dry ice cleaning for your printing equipment, you can always ensure that your printing operation produces top quality and operates at peak efficiency. Dry ice cleaning is a more effective cleaning solution that provides the ability to clean-in-place, without chemicals and without damage, which results in higher-performing machinery, increased quality, reduced scrap rates and prolonged equipment life of printing machines.

Dry ice cleaning print industry solutions in the real world

BENEFITS OF DRY ICE BLASTING

→ Decrease cleaning time and labour costs

→ Non-abrasive

No damage to substrates

→ Clean in-place

No disassembly required

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safe

Reduce harmful chemicals and tedious manual cleaning

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

Dry Ice Cleaning

Print Industry FAQ

How Does Dry Ice Clean Printing Equipment?

There are three primary factors that contribute to the dry ice cleaning process. The factors include Pellet Kinetic Energy, the Thermal Shock Effect, and the Thermal-Kinetic Effect. In order to better understand the cleaning practice, the process can be broken down into three stages – Impact, Cold, Expansion (ICE).

IMPACT – The impact of pellets creates a kinetic energy effect. The soft dry ice accelerated by compressed air at supersonic speeds.

COLD – The cold temperature of dry ice creates a thermal effect. The low temperature of dry ice (-78.9°C /-109°F) causes the bond to break between the contaminant (bacteria, dirt, paper) and the surface of the equipment.

EXPANSION – The expansion of the dry ice pellets. Dry ice pellets sublimate on impact, expanding in size and removing the contaminants.

How Can Dry Ice Blasting Be Used?

Dry ice blasting is the method of using carbon dioxide, in a pressurised form, to provide effective, sustainable and non-abrasive industrial cleaning. Dry ice blasting, or dry ice cleaning as it is also known, is one of the most reliable and resourceful practices for industrial settings and is typically used to clean printing machinery. The most common dry ice blasting applications include:

- Adhesive Removal

- Coating & Corrosion Removal

- Composite Tool Cleaning

- Core Box Cleaning

- Equipment Cleaning

- Historical Restoration

- Mould Removal

- Part Finishing

- Remediation

- Surface Preparation

- Weld Line Cleaning

Which Industries Do Cold Jet Work With?

Cold Jet engage with many different industries across Australia and the world. Our diverse clientele allows us to customise dry ice solutions to meet a wide variety of applications. The main industries that we engage with include:

- Aerospace and Aviation

- Automotive

- Contract Cleaning

- Engineered Wood

- Food and Beverage

- Foundry

- Medical Device

- Mining

- Oil and Gas

- Packaging

- Plastics and Composites

- Power Generation

- Printing

- Public Transportation

- Restoration and Remediation

- Rubber and Tires

- Textiles

How Much Does Dry Ice Cleaning Cost?

Dry ice blasting and cleaning costs come down the application of the equipment, the project scope and the type of equipment required.

Cold Jet are not the cheapest providers of dry ice printing solutions – nor should you want us to be. We design and manufacture all of our equipment through Cold Jet, and all of the services available deliver exceptional technology and good, old-fashioned customer service. We believe in prioritising quality, which means that when you work with Cold Jet Australia, you’re dealing with experts that take your printing cleaning projects seriously. To discuss how much your dry ice cleaning print industry project will cost, call us today on 1300 COLDJET.