RESTORATION & REMEDIATION

A faster and more

effective process for

remediation and restoration

Dry ice blasting is proven to be a more efficient and time saving

solution in remediation and restoration projects. The process

is non-abrasive, eliminates manual cleaning methods and does

not produce secondary waste, which reduces the amount of

time spent on encapsulation, waste collection and disposal.

CASE STUDIES

Revolutionise processes

to drive real results.

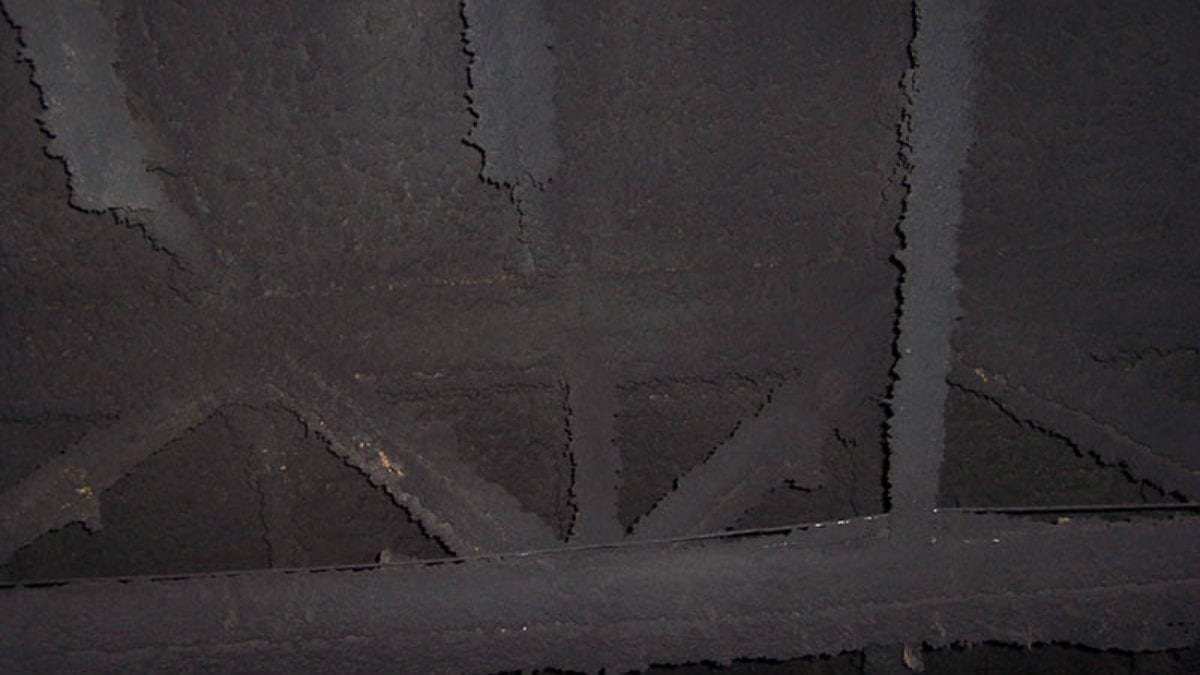

Fire and Smoke Remediation

Remove fire and smoke damage quicker and more efficiently

BENEFITS

Dry ice cleaning completely removes contaminants and damaged surfaces while removing odour and without creating secondary waste.

- Reduce remediation time

- Eliminate manual cleaning

- Reduce labour costs and project time

- No secondary waste

Reduce encapsulation and disposal costs - Chemical free process

Eliminate abrasive and harmful chemicals - Remove odour from fire damage

- Environmentally responsible

- Access tight and confined areas

SPECIFIC USE CASES:

- Wood

- Brick

- Metal

- Concrete

Mould Remediation

Remove 99.9% of mould spores faster

than traditional cleaning methods

BENEFITS

Dry ice blasting eliminates timely manual cleaning and does not create secondary waste.

- Reduce remediation time

- 99% mould spore removal on wood when IAQA standards are followed

- Eliminate manual cleaning

- Reduce labour costs and project time

- No secondary waste

Reduce encapsulation and disposal costs - Chemical free process

- Ability to deodourise affected areas

- Environmentally responsible

Will not harm surrounding areas

SPECIFIC USE CASES:

- Wood

- Brick

- Metal

- Concrete

Water and Flood Remediation

Efficiently remove mould and other

contaminants from water damaged surfaces

BENEFITS

Dry ice cleaning remediates flooded areas quicker and can access hard to reach areas, such as crevices and voids.

- Reduce remediation time

- 99% mould spore removal on wood when IAQA standards are followed

- Eliminate manual cleaning

- Reduce labour costs and project time

- No secondary waste

Reduce encapsulation and disposal costs - Chemical free process

- Ability to deodourise affected areas

- Environmentally responsible

Will not harm surrounding areas

SPECIFIC USE CASES:

- Wood

- Brick

- Metal

- Concrete

Historical Restoration

Safely restore historical items more quickly with non-abrasive cleaning method

BENEFITS

Dry ice cleaning eliminates abrasive hand tools and chemicals, while enabling a faster restoration process.

- Non-abrasive

Will not damage sensitive or delicate surfaces - Chemical free process

Eliminate abrasive and harmful chemicals - Reduce restoration time

Remove contaminants faster and more effectively - No secondary waste

Reduce encapsulation and disposal costs - Eliminate abrasive hand tools

- Environmentally responsible

Will not harm surrounding areas

SPECIFIC USE CASES:

- Adhesive and tar removal

- Fire and smoke damage

- Water damage

- Carbon buildup removal

- Failing paint removal

- Lead paint abatement

- Mould Remediation

- Corrosive contaminant removal

BENEFITS OF DRY ICE BLASTING

Complete restoration and remediation

projects in a fraction of the time

Dry ice blasting completely and safely removes contaminants from affected areas and does not produce secondary waste, which results in shorter project times and lower costs.

→ Reduced project time

Remove contaminants faster and more effectively

→ No secondary waste

Reduce encapsulation and disposal costs

→ Non-abrasive

Will not damage sensitive or delicate surfaces

→ Chemical free process

Eliminate abrasive and harmful chemicals

→ Eliminate manual cleaning

Reduce labour costs

→ Environmentally responsible

Will not harm surrounding areas

→ Versatile clean

Clean a varying degree of surfaces

→ Dry cleaning process

No added moisture

→ Ability to deodourise affected areas

Remove odour created by mould and smoke damage