DRY ICE BLASTING WOOD & ENGINEERED WOOD

A safer, reliable cleaning process that requires

less labour and eliminates manual cleaning

Revolutionised processes

offering exceptional results.

Looking for expert dry ice blasting wood services? You’ve come to the right place. Cold Jet are Australia’s leading team of experts providing dry ice blasting services for engineered wood and wood composites. Where the traditional cleaning process for tooling for engineered wood is labour intensive, time consuming and requires heavy load on resources, dry ice blasting is the ideal solution.

Dry ice blasting safely cleans engineered wood tooling and provides an environment in which equipment can operate better than ever before. Using dry ice cleaning methods for wood composites and engineered wood materials, you can rest assured materials are protected from damage and will be left cleaner and more reliable.

Dry Ice Blasting Wood & Engineered Wood

Dry ice cleaning quickly and effectively cleans composite wood production equipment without water, chemicals or secondary waste. Other benefits of dry ice blasting wood include:

- No secondary waste

- Reduced fire hazard

- Clean in-place

- No cool down required

- Reduce labour costs

- Non-abrasive

- Eliminate wear and tear on machinery

- Reduce downtime

- Increase employee safety

- Eliminate manual cleaning with chemical solvents

- Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

SPECIFIC USES:

- OSB presses

- Dryers

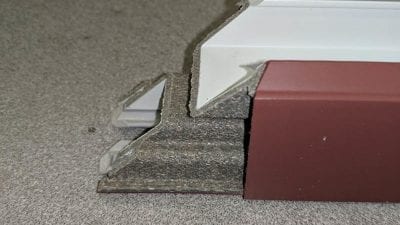

- Finger joint blade holders

- Glue applicators

- Peelers

- Lathes

- Pitch and resin removal

- Sanding belts

- Ventilation blades

- Wet scrubbers

- and more

Speak to a Dry Ice Wood Technician Today

Dry Ice Blasting Wood & Engineered Wood

Dry ice blasting wood services work with accelerated dry ice pellets. Dry ice pellets are blasted at the affected areas of engineered wood, where the solution is sublimating on impact; resulting in an effective clean, with no residue or waste produced. The low temperature and powerful impact of dry ice mean that all contaminants are lifted from the engineered wood surface, without further damaging any materials. The end result of dry ice blasting is the composite woods being cleaner than ever before.

Using our technology for dry ice blasting for engineered wood, dry ice is much more sustainable than other cleaning methods. Our equipment utilises materials that are inert, non-conductive and non-corrosive. There is no secondary toxic waste, moisture, or residue produced when using our dry ice blasting methods. As such, our methods do not produce any harmful chemicals or hazardous waste.

BENEFITS OF DRY ICE BLASTING WOOD

The benefits of dry ice blasting for engineered wood are plentiful. Dry ice blasting wood services eliminates the manual cleaning of engineered wood presses, dryers and vents, while eliminating employee exposure to unsafe conditions. Dry ice cleaning is a safer and more effective cleaning solution for composite wood presses and ancillary equipment, – there is no disassembly of equipment required, and dry ice blasting eliminates the need for harsh chemicals and laborious cleaning practices.

The typical cleaning process for tooling for engineered wood is time-consuming, labour intensive and requires employees to work within close proximity to machines, hot residue and dust. Dry ice blasting for wood and engineered provides a no-contact cleaning solution that is faster, safer and more effective. Cold Jet are pleased to present a sustainable, resourceful and efficient solution for engineered wood composites. Other benefits include:

→ Decrease cleaning time and labour costs

→ Non-abrasive

→ Clean in-place

→ Increase productivity and reduce downtime

→ Non-conductive cleaning process

→ Employee safety

→ Environmentally responsible

→ Improve part quality and reduce scrap

→ No secondary waste stream

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

Frequently Asked Questions About Dry Ice Blasting for Wood

Between our dry ice blasting wood services, dry ice production services and our exceptional dry ice machinery, we’re the experts in dry ice offerings in Australia. We’re renowned for providing dry ice with the highest density, and we’re extremely proud of that. Striving to deliver the highest quality services and products, Cold Jet are committed to maintaining an exceptional standard, including with all customer service interactions dry ice blasting.

As such, we’ve put together a ‘frequently asked questions’ section to answer all common questions to do with dry ice blasting wood and engineered wood services.

How Does Dry Ice Clean Engineered Wood?

There are three primary components that contribute to the dry ice blasting wood process. The components include Pellet Kinetic Energy, the Thermal Shock Effect, and the Thermal-Kinetic Effect. In order to better understand the cleaning practice, the process can be broken down into three stages – Impact, Cold, Expansion (ICE).

IMPACT – The impact of pellets creates a kinetic energy effect. The soft dry ice accelerated by compressed air at supersonic speeds.

COLD – The cold temperature of dry ice creates a thermal effect. The low temperature of dry ice (-78.9°C /-109°F) causes the bond to break between the contaminant and the engineered wood surface.

EXPANSION – The expansion of the dry ice pellets. Dry ice pellets sublimate on impact, expanding in size and removing the contaminants.

Why Is Dry Ice Better Than Other Cleaning Methods?

Dry Ice Blasting for Wood Is Safe

Dry ice manufacturing, production and blasting for cleaning is safe, as it relies purely on carbon dioxide. The process of dry ice blasting for cleaning engineered wood is non-toxic and non-flammable. In fact, dry ice is so safe that the use has been approved for commercial use around food by the EPA, FDA and USDA. With a qualified professional, dry ice blasting for remediation is one of the safest cleaning options.

Dry Ice Eliminates Pollutive Secondary Waste

When the dry ice impacts the surface being cleaned, it sublimates – turning directly from a solid to a gas—and thus does not produce secondary waste. Similar cleaning techniques leave behind a residue that must be cleaned up afterwards, along with the offending contaminant. This media can become hazardous and create downstream contamination and harm the surrounding area and installations. Say goodbye to secondary wastes with dry ice blasting for engineered wood tools and equipment.

Dry Ice Blasting Saves Time

Dry ice blasting, particularly for equipment and wood cleaning, is incredibly time-efficient when compared to other cleaning methods. Dry ice blasting offers a significantly faster process that leads to minimised downtime and an increase in productivity. A reduction in labour and the lengthy processes that typically come with cleaning mean that dry ice blasting wood services are incredibly time saving and efficient.

What Else Can Dry Ice Be Used For?

In the case of dry ice blasting for wood, the technique is extremely effective for cleaning composite wood materials. Due to the plethora of benefits of using dry ice blasting, the practice can also be used for a wide range of applications, including:

- Coating & Corrosion Removal

- Composite Tool Cleaning

- Core Box Cleaning

- Equipment Cleaning

- Historical Restoration

- Adhesive removal

- Part Finishing

- Surface preparation

- Surface Preparation

- Rust Removal

- Weld Line Cleaning

- Dry Ice Manufacturing for Airline Catering

- Dry Ice Cooling in Food Processing

Does Dry Ice Blasting Leave A Residue?

No – dry ice blasting does not leave residue or waste when cleaning wood composites. Dry ice sublimates upon impact with the surface being cleaned, which results in no secondary waste, no residue and no introduction of moisture. This eliminates extra clean-up, disposal of secondary waste streams and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components before cleaning. This significantly reduces the duration of cleaning projects and the resulting shutdowns.

Which Industries Use Dry Ice?

At Cold Jet, we work with a variety of occupations that require the assistance of dry ice blasting, dry ice cleaning, dry ice production and dry ice manufacturing equipment. We also deliver leading dry ice training to those who regularly work with dry ice materials.

Covering all aspects of dry ice, we strongly believe that we can provide a solution for almost every industry with our industry-leading technology. Over the years, we have acquired an extensive and diverse portfolio of clients, showcasing our depth in dry ice solutions. Here are the main industries that we typically work with at Cold Jet:

- Aerospace and Aviation Industry

- Automotive Industry

- Contract Cleaning Industry

- Engineered Wood Industry

- Food and Beverage Industry

- Foundry Industry

- Medical Device Industry

- Mining Industry

- Oil and Gas Industry

- Packaging Industry

- Plastics and Composites Industry

- Power Generation Industry

- Printing Industry

- Public Transportation Industry

- Restoration and Surface preparation Industry

- Rubber and Tires Industry

- Textiles Industry

If you have any questions, queries, or would like to talk to one of our dry ice specialists, please do not hesitate to get in touch today. Talk to our expert technicians to learn more about what our dry ice technology can do for you.