AUTOMOTIVE DRY ICE BLASTING

Dry ice blasting allows you to meet stringent industry demands

while increasing production uptime in the automotive industry

Automotive dry ice blasting is one of Cold Jet’s primary service offerings. Working with a diverse clientele in the automotive industries, we provide a number of dry ice blasting applications that transform lengthy operations in automotive workshops. Cold Jet deliver leading dry ice solutions for the automotive industry.

Dry ice cleaning helps automotive facilities solve a variety of cleaning challenges, allowing mechanics and manufacturers to increase productivity and improve part quality. Relying on dry ice blasting for Automotives means reducing cleaning time and production downtime while prolonging equipment life.

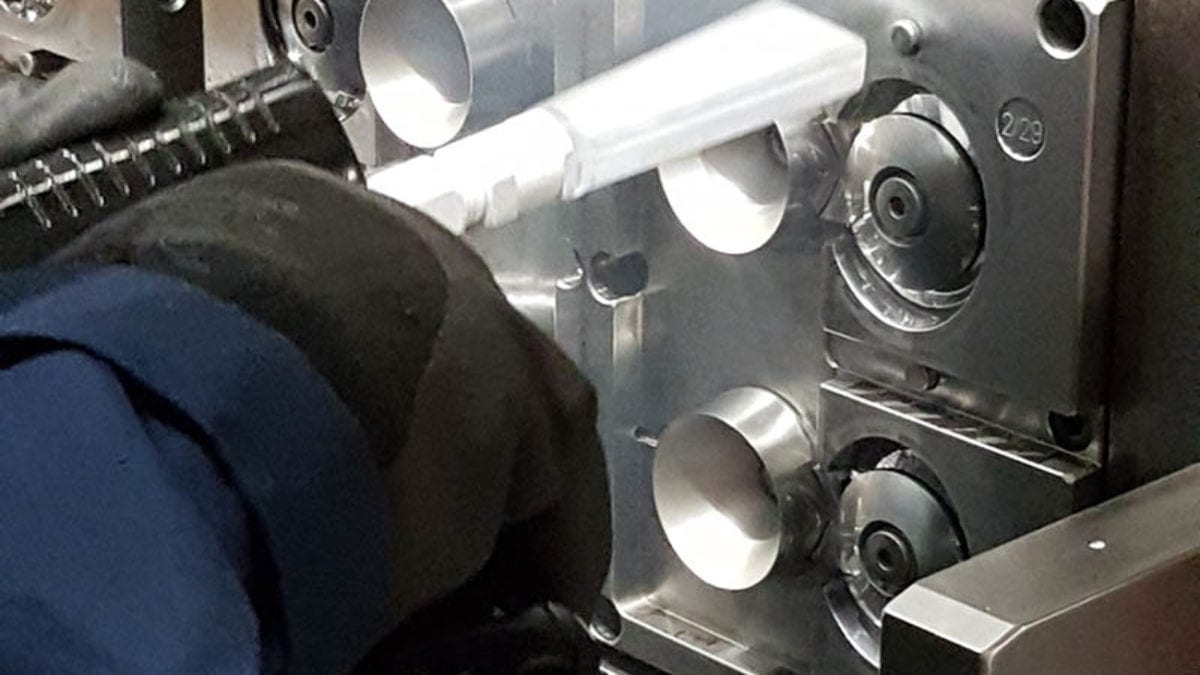

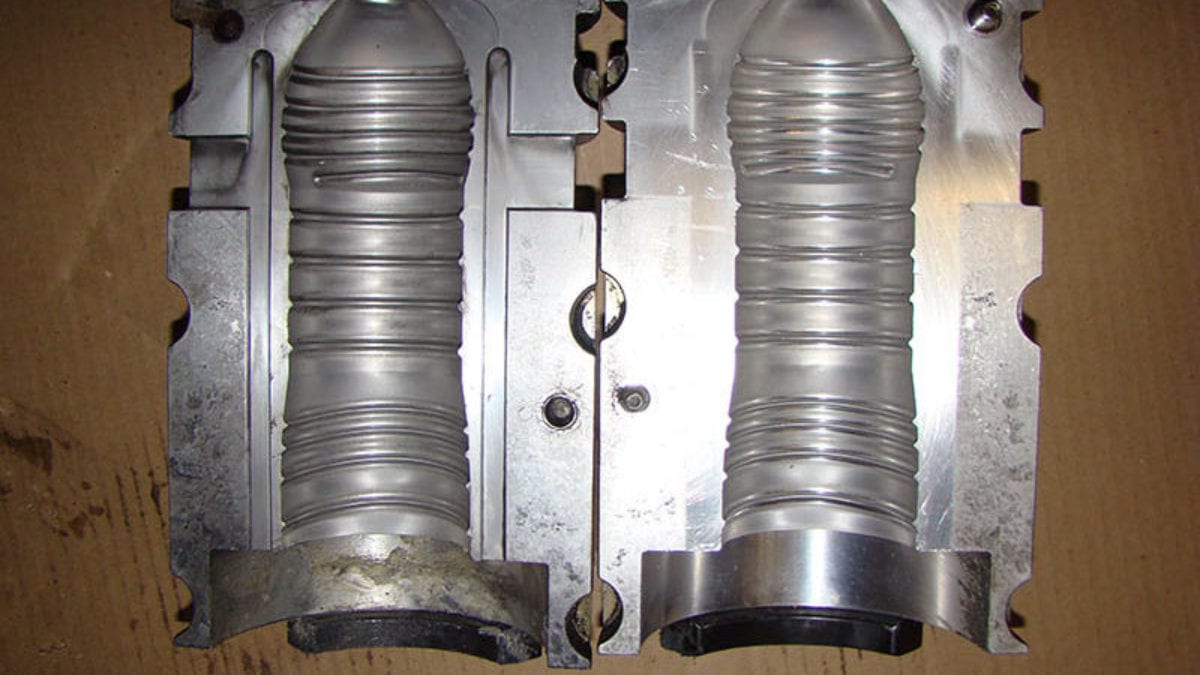

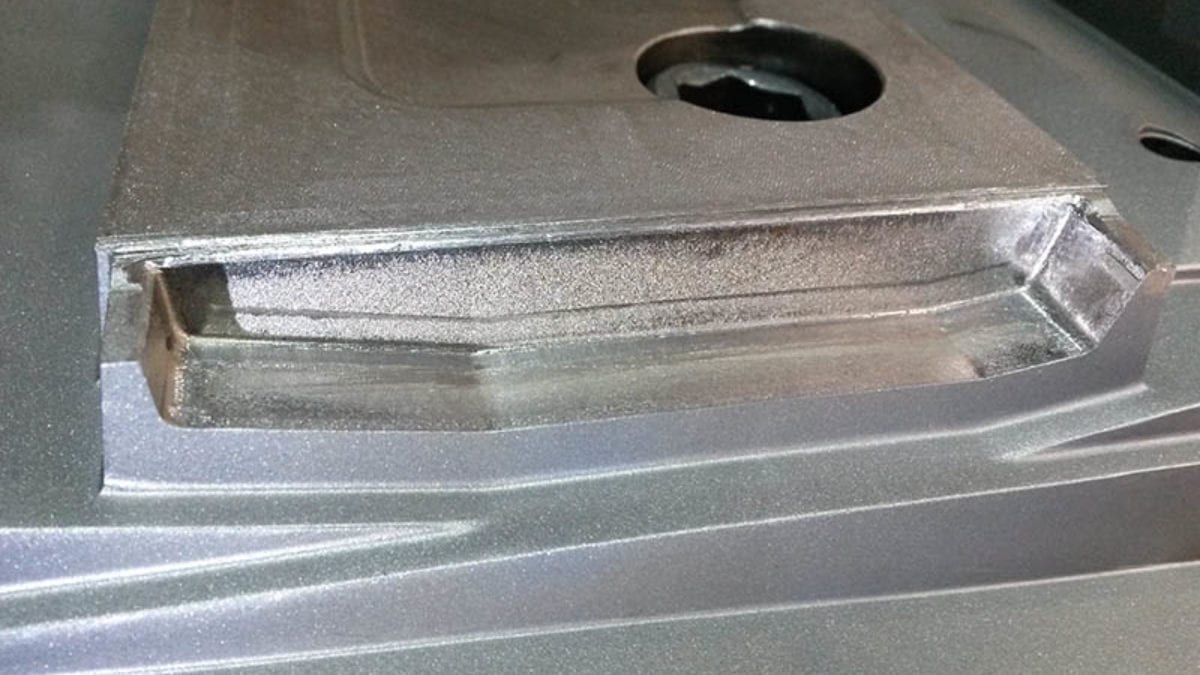

Mould Cleaning

Improve productivity by reducing downtime with automotive dry ice blasting. Dry ice cleaning is a non-abrasive method that safely cleans moulds online, at operating temperatures.

- Improve product quality

- Clean in-place

- Little to no disassembly required

- Non-abrasive

- No damage to moulds

- Reduce scrap

- Cleaner moulds lead to higher quality

- Meet stringent industry demands

- 6-Sigma, Kaizen, 5S, TPM (Total Productive Maintenance)

- Reduce production downtime

- Clean quicker and without cooldown or disassembly

- Decrease cleaning time and labour costs

- Eliminate painstaking manual cleaning

SPECIFIC USES:

- Injection moulds

- Blow moulds

- Compression moulds

- Urethane moulds

- Textured moulds

- Slush moulds

- Technical moulds

- Extrusion dies

- Rotational moulds

- LSR and LIM moulds

- Thermoform moulds

Surface Preparation

Prepare surfaces with a dry process that allows for immediate coatings/paint application. Automotive dry ice blasting includes a dry cleaning process that eliminates the need for aqueous or chemical solutions on paint lines.

- Dry process allows for immediate paint or coating after cleaning

- No secondary waste

- Reduce disposal costs

- Non-abrasive

- Will not damage parts

- Improve product quality

- Environmentally responsible

SPECIFIC USES:

- Interior parts

- Exterior parts

- Cleaning surfaces before RTVs

Speak to an Automotive Dry Ice Technician Today

Paint & Coating Booth Cleaning

Reduce production downtime and scrap rates. Automotive Dry ice blasting provides a quicker and more effective cleaning process for spray booths, reducing the risk of unplanned production downtime.

- Reduce downtime associated with cleaning

- Reduce waste disposal costs

- Eliminate water and secondary waste

- Clean more effectively

- Increase production efficiencies

- Maximise equipment life

- Environmentally responsible

SPECIFIC USES:

- E-coat and powder coat lines

- Paint hooks

- Spray booths

- Paint shop rollers

- Guide rails

- Reduction gearboxes

- Perforated shielding

- Flooring

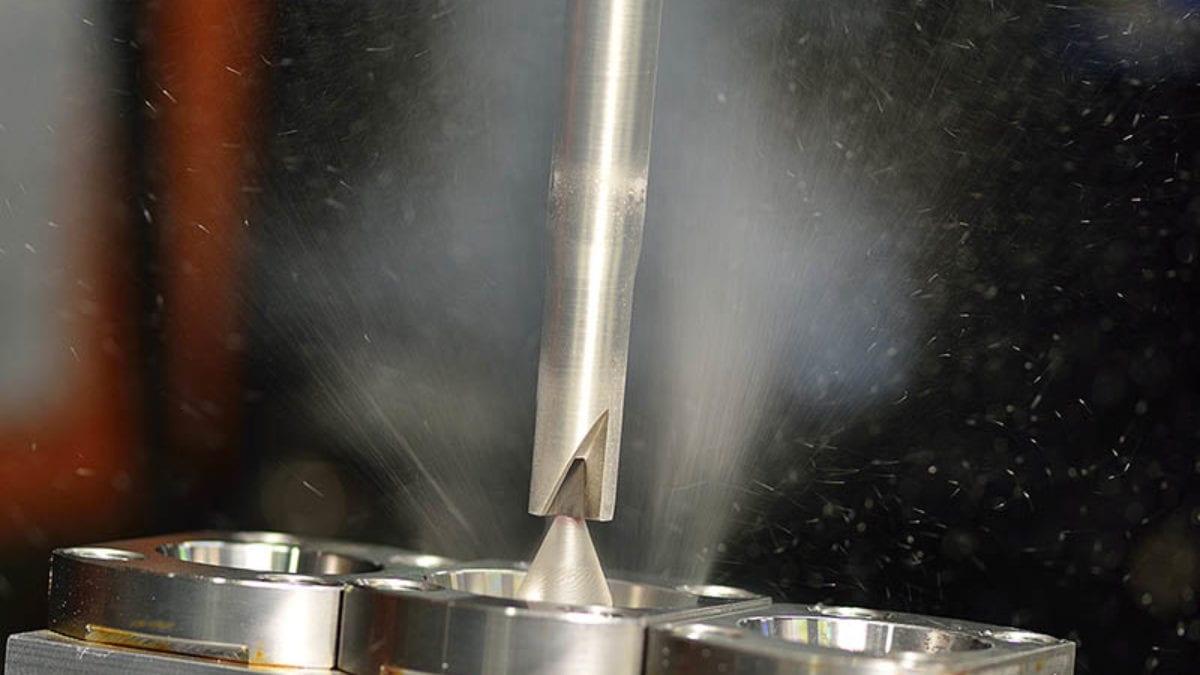

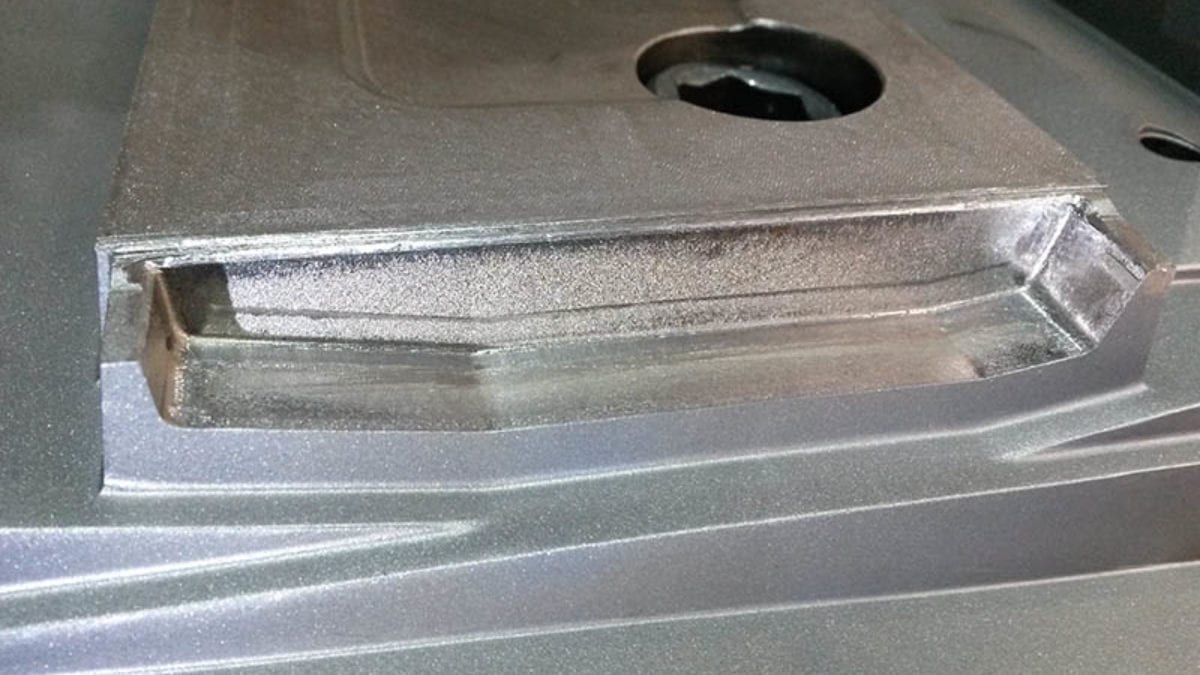

Composite Tool Cleaning

Meet stringent industry demands in your automotive facility while protecting delicate tool surfaces and finishes. Automotive dry ice blasting quickly cleans a variety of tooling made of a varying degree of materials.

- Reduce production downtime

- Maximise tooling life

- Environmentally responsible

- No secondary waste

- Reduce cleaning time and labour costs

- Non abrasive

- No damage to tooling surfaces

- Clean a variety of materials with a single machine

- Clean tooling in place

- Eliminate chemicals and solvents

SPECIFIC USES:

- Compression moulding

- Resin transfer moulding

- Extrusion

- Pre-pregging

- Wet-layup

- Teflon-coated tools

- Highly-polished tools

- Post-processing equipment

- Autoclave flooring walls

- PEEL, Kevlar, E-Glass, S-Glass, Spectra, Boron, Pultrusion, etc.

- LIM moulding

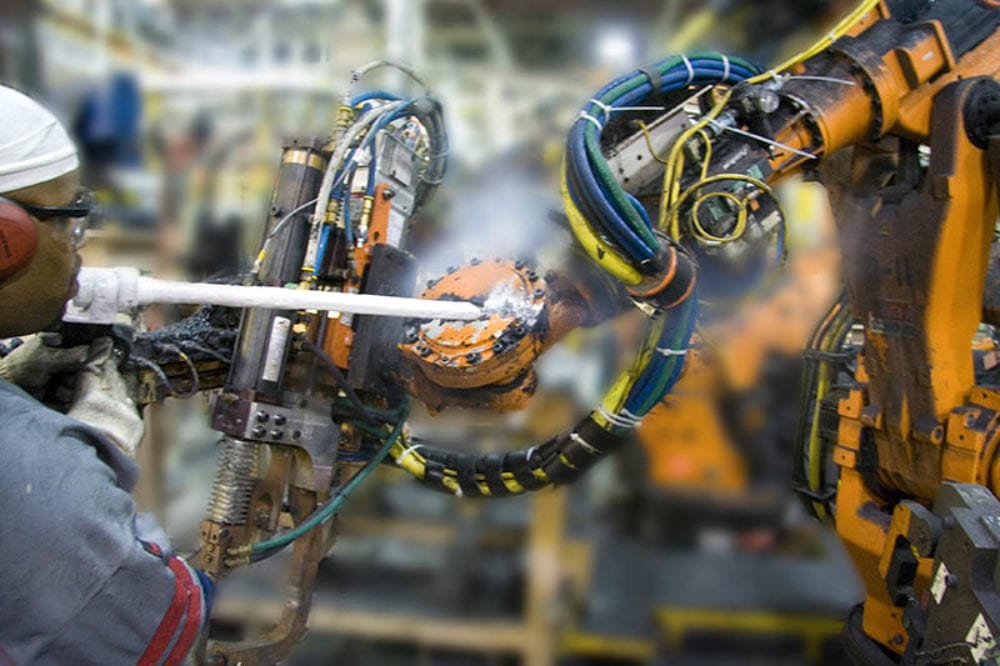

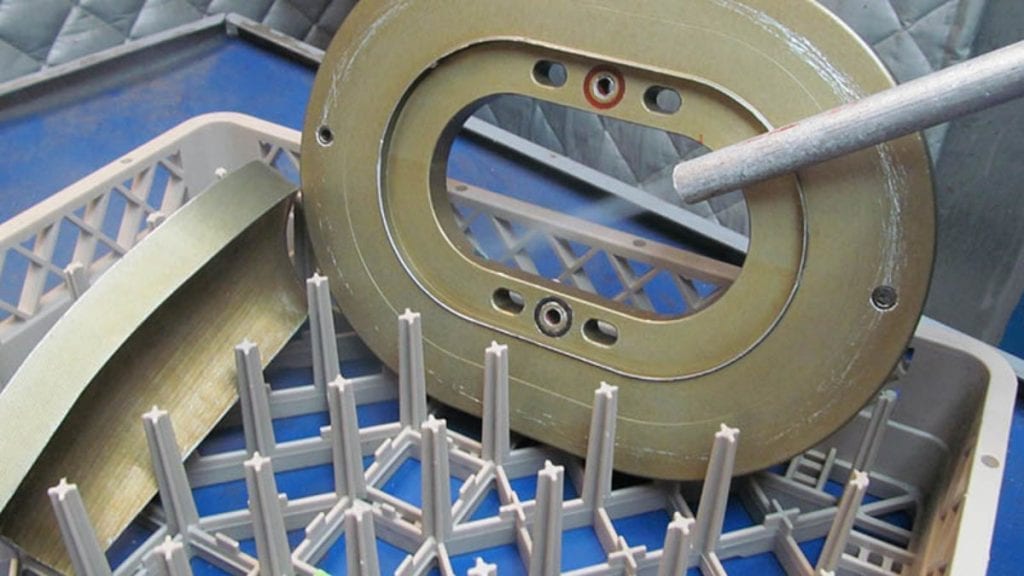

Weld Line Cleaning

Improve efficiency and accuracy of automated weld lines. Automotive dry ice blasting eliminates misalignment, breakdowns and scrap by effectively removing weld slag and spatter buildup.

- Reduce scrap rates

- Maximise tooling life and decrease fixture repair

- Non-abrasive

- Will not damage sensors

- Replaces ineffective, costly and labor intensive cleaning methods

- Minimise downtime

- No secondary waste

- Environmentally responsible

- Clean online

- No cool down required

SPECIFIC USES:

- Robot joints

- Transfer cases

- Shuttle jigs

- Diamond plates

- Trunnions

- Weld tables

- Fixtures

- Proximity switches

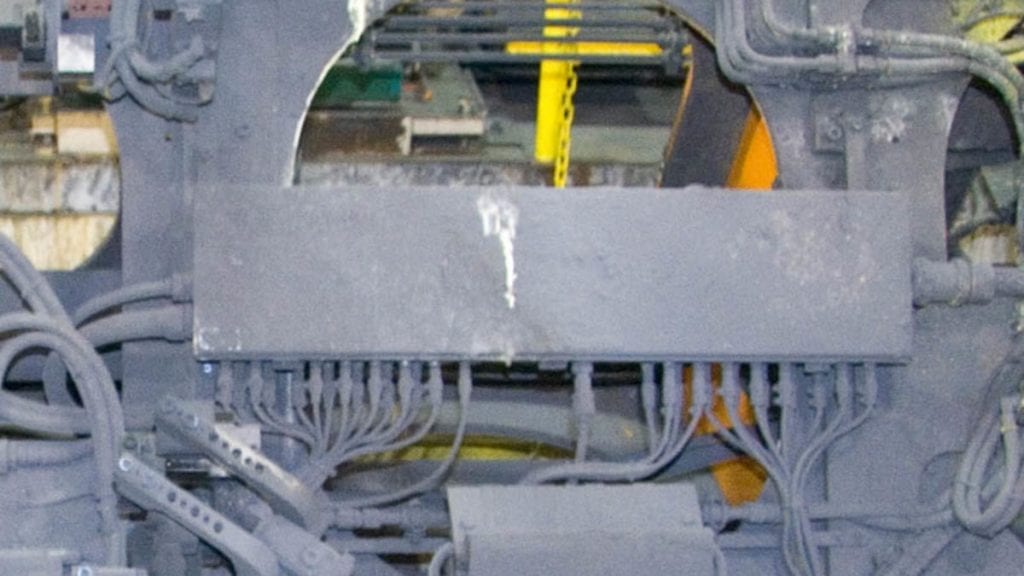

Foundry Cleaning

Significantly reduce cleaning time that typically results in production downtime. Automotive dry ice blasting enables facilities to clean machinery and tooling in-place, at operating temperatures, without the risk of damage to automotive and foundry equipment.

- Reduce production downtime

- Eliminate mould disassembly

- Clean while hot and in-place

- Clean more effectively

- Eliminate waste disposal cost

- Non-abrasive

- No damage to tooling

- Environmentally responsible

- Deliver superior as-cast finish

SPECIFIC USES:

- Conveyors

- Core boxes and vents

- Die cast tooling

- Permanent aluminium moulds

- Refractory coating

- Resins and release agents

- Semi-solid casting and forging tooling

- Shell core moulds

- General part cleaning

- General equipment and facility cleaning

CASE STUDIES

Revolutionise processes

to drive real results.

Parts Finishing

Quickly and safely deburr and deflash parts. Automotive dry ice blasting offers a faster and more uniform flash and burr removal process that does not cause damage to the part.

- Reduce production downtime

- Eliminate mould disassembly

- Clean while hot and in-place

- Clean more effectively

- Eliminate waste disposal cost

- Non-abrasive

- No damage to tooling

- Environmentally responsible

- Deliver superior as-cast finish

SPECIFIC USES:

- PEEK

- PBT

- Acetal

- Nylon

- LCP

- ABS

- UHMWPE

- Nitinol

General Equipment Cleaning

Reduce cleaning time and production downtime while prolonging equipment life. Automotive dry ice blasting quickly and effectively cleans production equipment without water, chemicals or secondary waste.

- Reduce cleaning time

- Eliminate manual cleaning with harmful chemical solvents

- Non-conductive cleaning process

- No secondary waste

- Non-abrasive

- Eliminate wear and tear on machinery

- Reduce risk of unplanned production stoppages and costly repairs

- Environmentally responsible

- Clean in-place

- No disassembly required

- Enhance Total Productive Maintenance (TPM) programs

SPECIFIC USES:

- Production equipment

- Ceilings and walls

- Equipment degreasing

- Electric motors and electric boxes

- Control panels

- Pipes, hoses and fittings

- Conveyors

- Cooling fans

- Hydraulic parts

- Robotics

- Sanding belts

- and more

TESTIMONIALS

Thousands of customers

around the world rely on Cold Jet

With a global install base of 15,000+ that consists of companies

large and small – Cold Jet delivers real value.

WE’RE HERE TO HELP.

Interested, but not sure where to start?

Contact us today to learn more about how dry ice blasting is used in your industry.